Registration for the Siemens Industrial Automation Golden Comprehensive Course (for the year 1403)

Dear friends, we would like to inform you that the Siemens Industrial Automation Training Course , the Golden Comprehensive Package, by Engineer Faraji, is currently being held semi-privately in the MrFaraji Group (“Matin Comprehensive Intelligence Institute”) in Tehran in 1403.

Engineer Faraji is teaching practical lessons in the Golden Age.

This training course includes the following:

- PLC S7 Basic Training (S7-300/400)

- Advanced PLC S7 Training (S7-300/400)

- WinCC SCADA Training

- TIA Portal V16 Training (S7-1200, S71500)

- Siemens Touch Panel (HMI) programming training with TIA Portal software

- Profibus industrial network training in TIA Portal

- Profinet industrial network training in TIA Portal

- Training on programming and parameterizing the Sinamics G120 drive in TIA Portal

- Modbus industrial network training in TIA Portal

- Advanced Servo Drive and Motion Control Course in TIA Portal

- PID Control training in STEP7 and TIA Portal software

- Training in command and document reading

- Eplan training

Those who are interested can send a WhatsApp message to 09939643266 (Registration and Consulting) to coordinate registration. Below, we will take a closer look at the course content and its objectives.

Course Name: Siemens Automation Golden Comprehensive Course

Course instructor: Engineer Ahmad Faraji and technical team trainers MrFaraji

About the teacher:

- Author of industrial books on Siemens industrial automation training (10 volumes so far)

- Instructor of training courses in various industries in the country

- Executor of industrial automation projects in factories and industries

Click here to view the list of books authored and courses held by Engineer Ahmad Faraji .

Course duration: 200 hours in person + 60 hours of educational videos

The duration of this course is about 200 hours of face-to-face classes (practical in Tehran) which are held in Siemens equipped workshops in the MrFaraji group (“Matin Comprehensive Intelligence Institute”). Also, for further preparation of the learners, about 60 hours of educational videos taught by Engineer Ahmad Faraji are provided to the learners before the start of the face-to-face sessions so that the learners can participate in the face-to-face sessions with high preparation while watching the videos and doing exercises at home. Also, during the course, some educational books and pamphlets written by Engineer Faraji are provided to the learners.

Course objectives: Immigration (to Germany-Europe-USA) and domestic projects

The educational topics of the Siemens Automation Golden Comprehensive Course have been selected in such a way that the learners of this course (provided they follow the educational programs provided by the instructor) will achieve the technical ability to work abroad (especially Germany) or to implement industrial projects in Iran. Along the way, the dear learners are constantly examined and monitored by the Mrfaraji technical team and their strengths and weaknesses are evaluated. Those who need more work and practice attend the training workshop outside of class time and practice more under the supervision of the MrFaraji team trainers.

Figure (3) Practical work of golden period learners in the Siemens workshop

Figure (4) Practical work of golden period learners in the Siemens workshop

Note: It should be noted that people who intend to immigrate to Germany must, in addition to participating in the Golden Period, also learn German to level B2.

Thematic review of the Siemens Golden Age headline

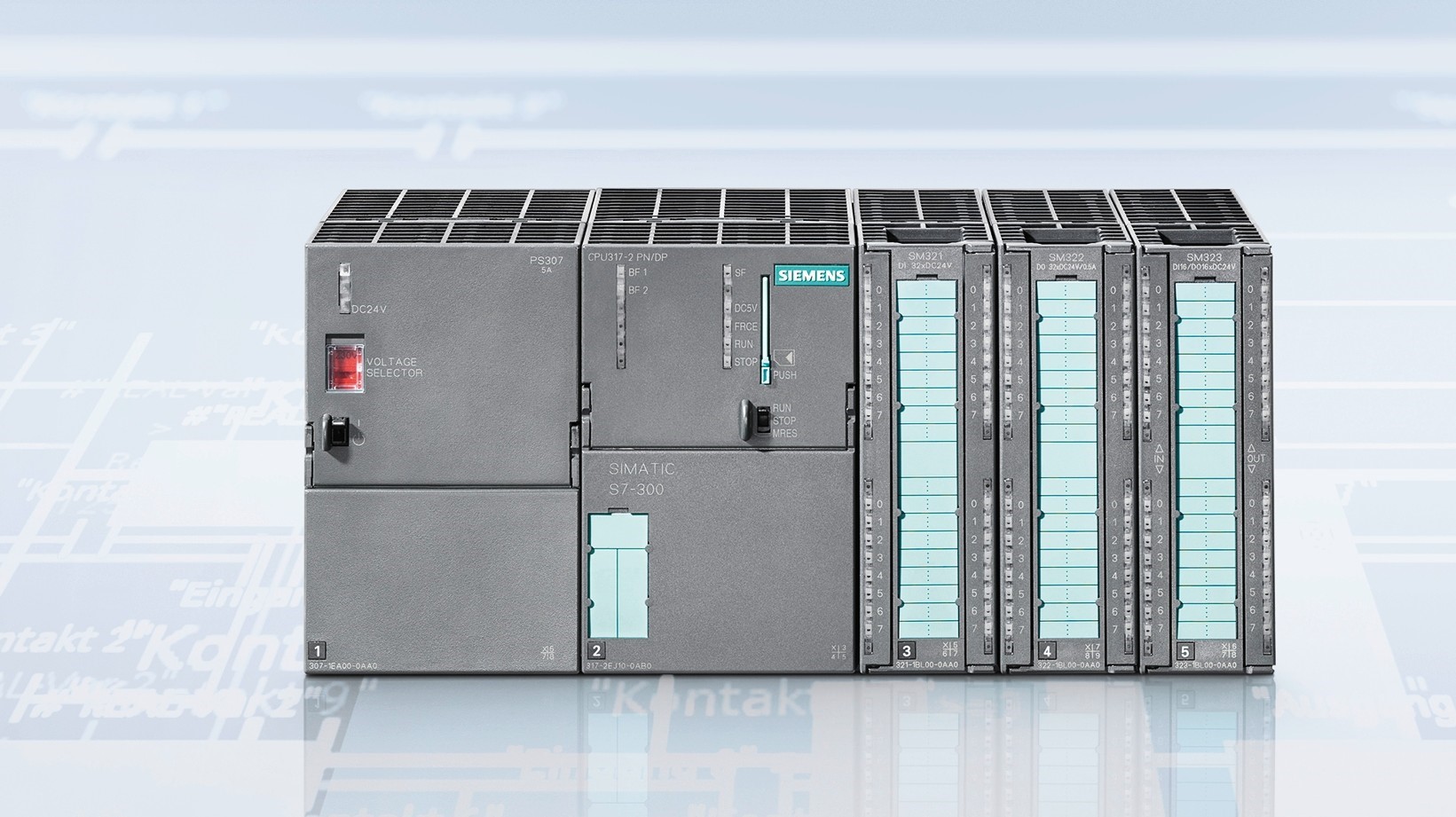

Siemens S7-300/400 PLC

Among the important types of Siemens PLCs worldwide and in Iran, we can mention the two families of Siemens PLCs: S7-300 and S7-400.

Figure (5) Image of S7-300 PLC

Figure (6) Image of PLC S7-400

These PLCs have been widely used in domestic industries as controllers for industrial production lines. Today, it is necessary for specialists (usually with different electrical backgrounds) to learn how to program and work with these PLCs because we still encounter this type of PLC in many industries and projects.

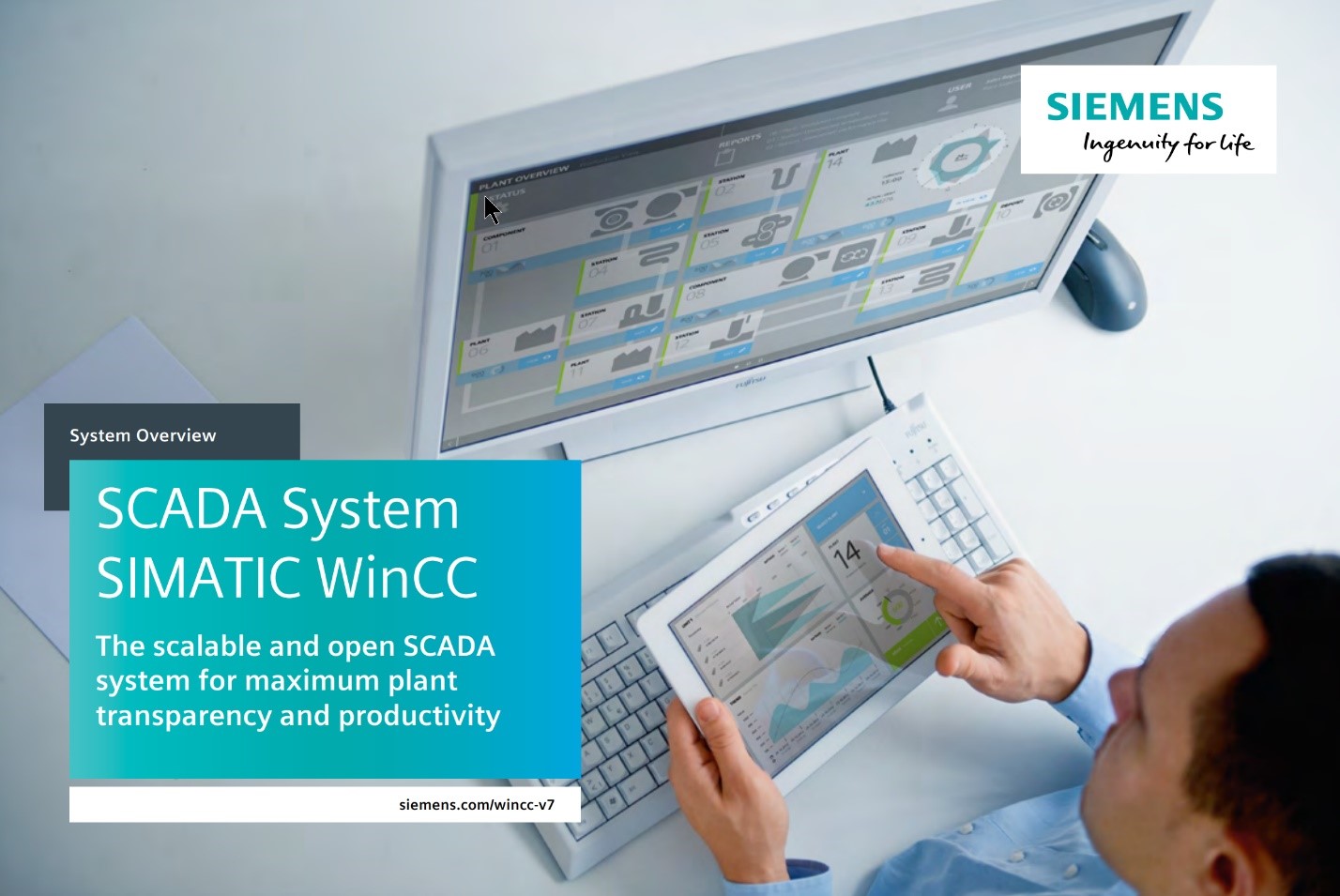

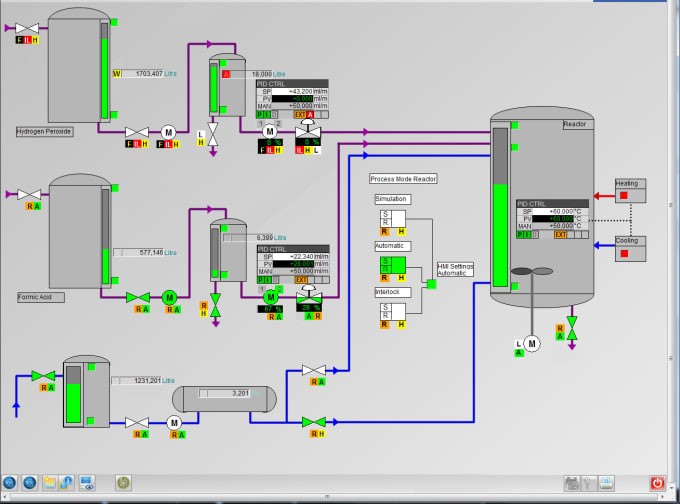

WinCC SCADA software

WinCC SCADA software is one of the important and powerful Siemens software for designing computer-based monitoring systems. Using this software, you can convert a regular or industrial computer into a monitoring system and through it send control commands to the PLC and display process or production line information graphically.

Figure (7) WinCC SCADA software

Figure (8) Runtime environment related to WinCC SCADA

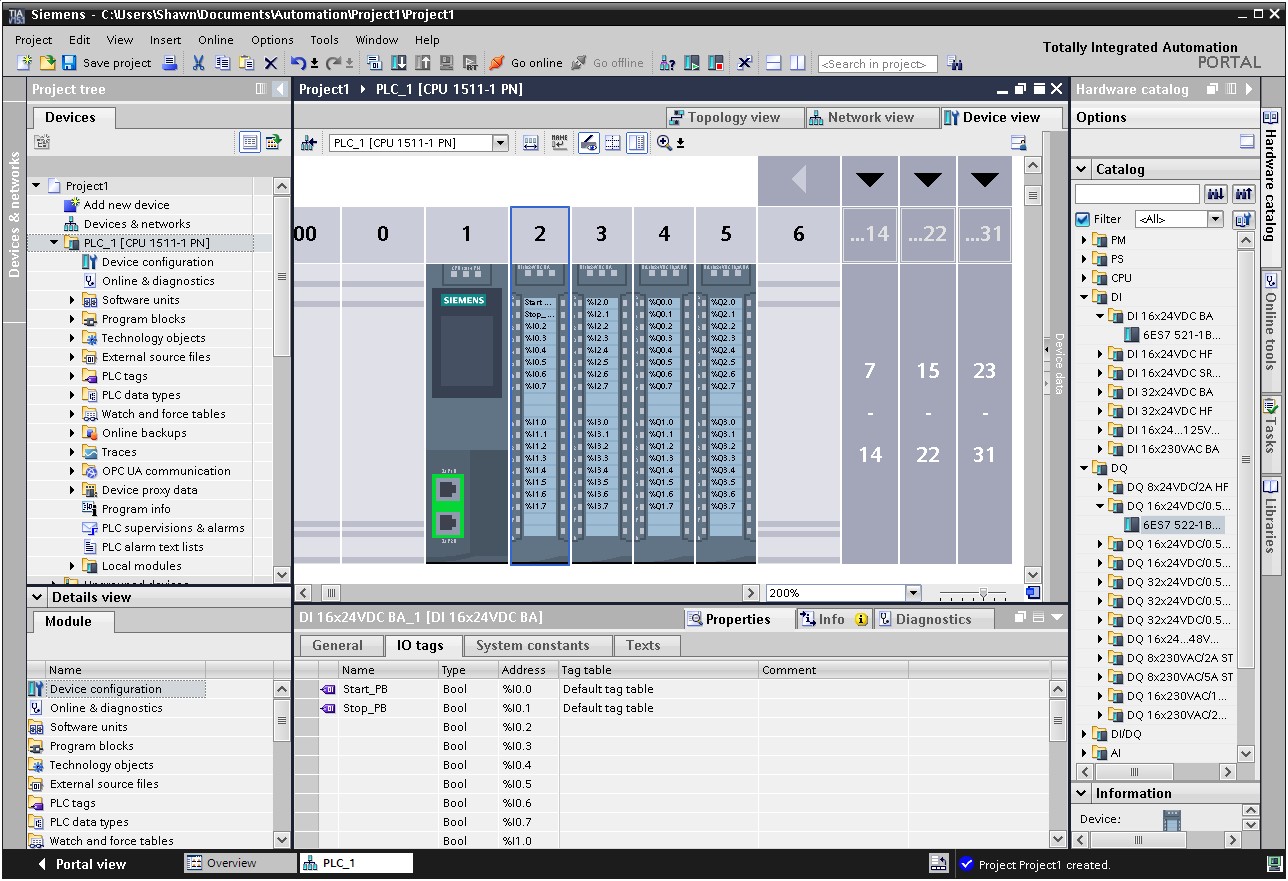

TIA Portal software

TIA Portal is a comprehensive and new automation software from Siemens that has many features and has replaced older Siemens software in new projects. Using this software, the following equipment can be programmed:

- Types of PLCs with ET CPU-S7-1500-S7-1200

- New PLC S7-300 and PLC S7-400 models

- New Siemens HMI models

- New Siemens drive models

Figure (9) S7-1500 PLC and TIA Portal software

Figure (10) TIA Portal software environment

PLC S7-1200

It is considered a small and medium-range PLC among Siemens PLCs and is widely used in industrial projects in domestic industries. This PLC has replaced the Siemens PLC S7-200, but its capabilities go far beyond the S7-200.

Figure (11) Image of PLC S7-1200

PLC S7-1500

It is considered a powerful PLC among Siemens PLCs and has many features and capabilities. In projects outside DCS, it can be used as a replacement for PLC S7-300/400. This type of PLC is widely used in projects abroad (especially in Germany).

Figure (12) Image of PLC S7-1500

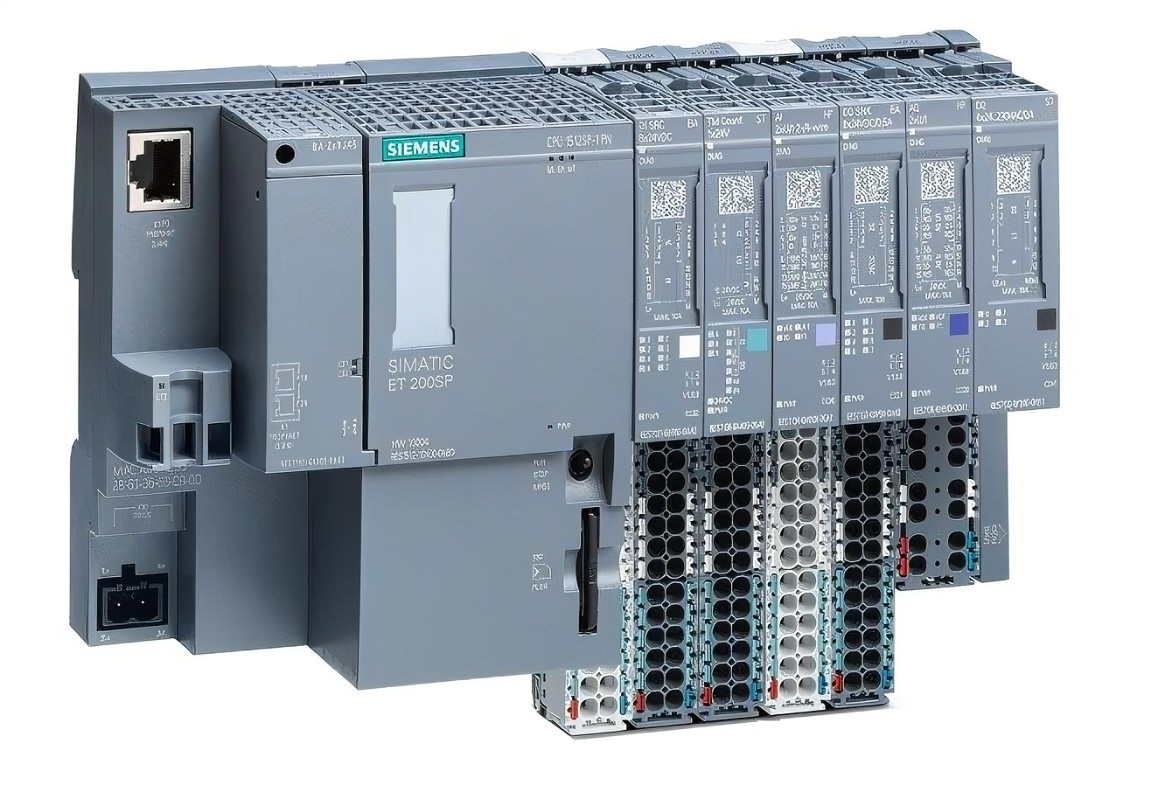

ET200SP CPU

It is considered a mid-range PLC, with capabilities greater than the S7-1200 PLC and less than the S7-1500. This type of PLC is also programmed using the TIA Portal software.

Figure (13) ET200 SP CPU image

Siemens Touch Panels (HMI)

In industry, it is necessary for the production line operator to be able to apply the desired commands to the control system and also view the process information. For this purpose, it is necessary (usually) to place an operator panel next to the production line. In the past, hardware panels including keys, knobs and lamps were used for this purpose, but now graphic operator panels called HMI are used. HMI has its own processor and can be programmed by various software and connected to the PLC.

Figure (14) Some examples of Siemens HMI

Siemens, as one of the leading companies in the field of industrial automation, has been manufacturing and offering a variety of HMIs with medium to advanced capabilities. Previously, Siemens HMIs were programmed using WinCC Flexible software, but today, new Siemens HMIs are programmed using TIA Portal software.

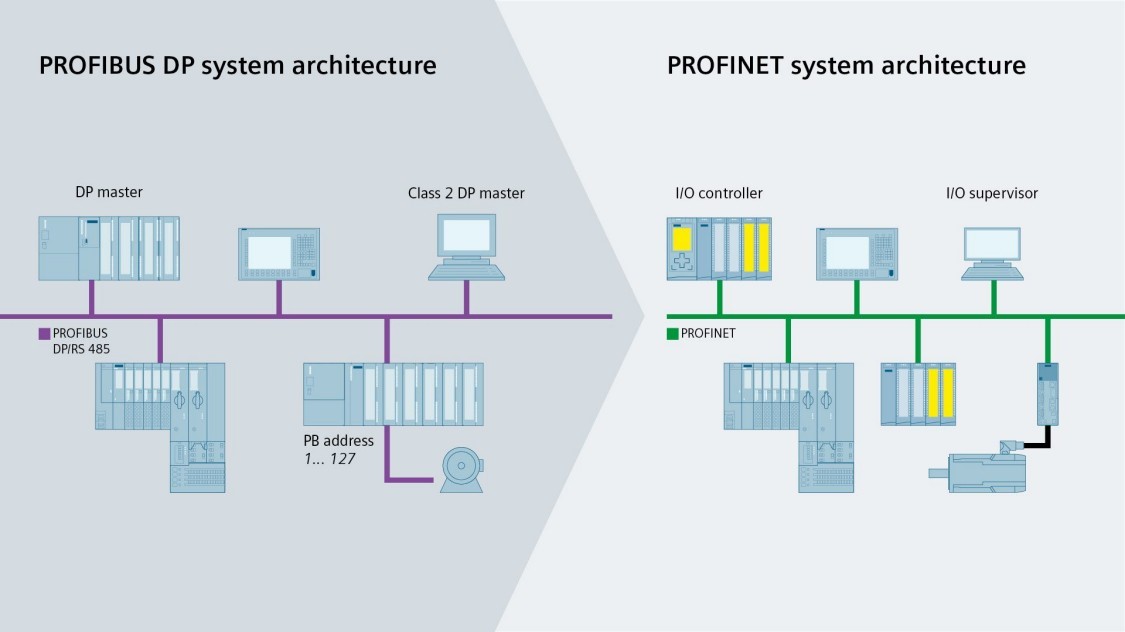

Profinet industrial network in TIA Portal

One of the relatively new networks in the industry is the Profinet network, which supports the applications of networks such as Profibus and Ethernet simultaneously. This network can establish communication between monitoring and control systems at the Plant level or between several control systems. It can also establish communication between PLCs with equipment such as Remote I/O (in Siemens, ET200) and drives, etc.

Figure (15) Comparison of Profinet and Profibus networks

Sinamics G120 drive

One of the important drives from Siemens in industrial projects is the Sinamics G120 drive. This drive is programmable by TIA software and in some models it also has Profinet network connectivity.

Figure (16) Sinamics G120 drive

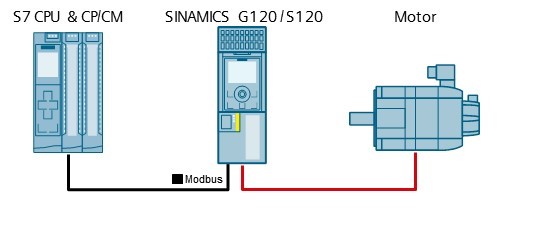

Modbus industrial network

Modbus is an industrial standard network that was initially created by Modican in 1979 and gradually developed. Today, Modbus has various protocols, each of which has its own specific functionality. Among them, the two protocols RTU and TCP/IP (also abbreviated as Modbus TCP) are more widely used in industry and many PLCs have communication ports related to them.

Figure (17) Using Modbus industrial network in Siemens systems

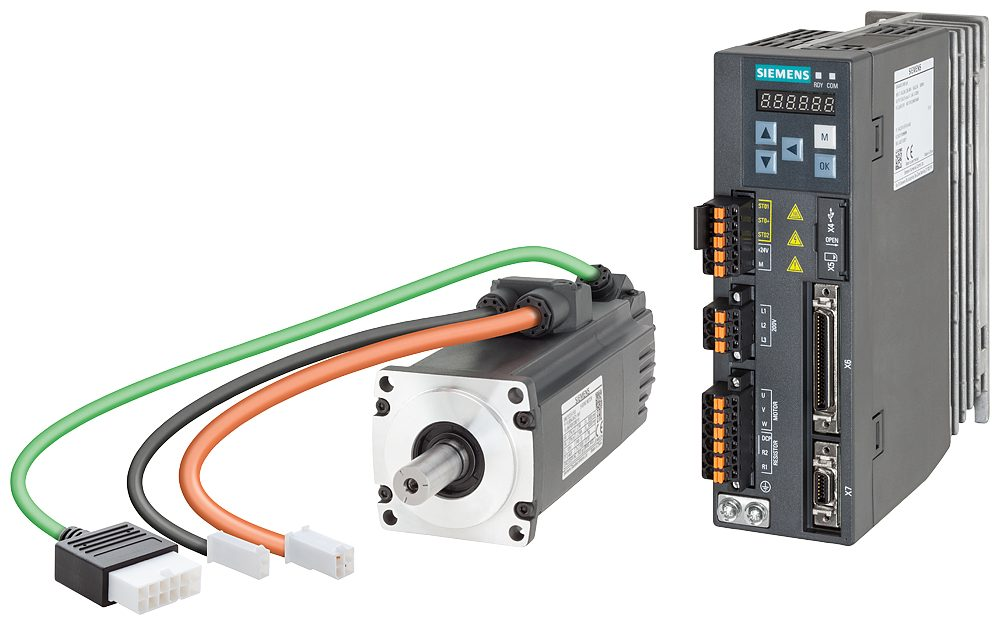

Motion Control

One of the most widely used equipment in industrial systems (mechanized systems) is the servo motor and servo drive, which is used for precise motion control. In this regard, Siemens has produced various servo motors and servo drives, one of which is the V90 family servo drive.

Figure (18) Sinamics V90 servo drive and its servo motor

SEW drive

One of the most widely used drives in industries for heavy work is the SEW drive, which is widely used in the automotive industry, the packaging sector of petrochemical industries, the home products manufacturing industry, and so on in Iran and Germany.

Figure (19) SEW drive available in the school

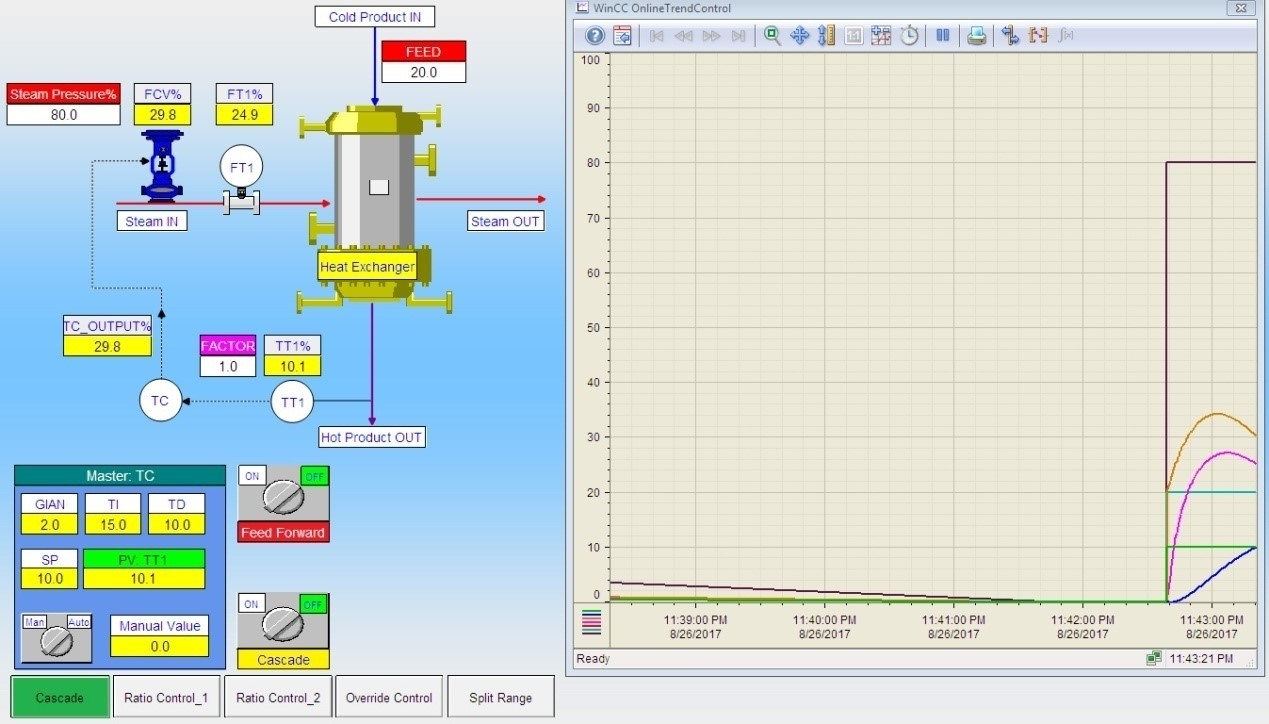

PID Control

PID as a control method in closed-loop systems for precise quantity adjustment Process parameters such as temperature, pressure, flow, level, etc. Siemens PLC types for PID control have various blocks and functions that are essential for industry professionals to learn.

Figure 20

Eplan software

Eplan software is a very powerful and multi-purpose software for drawing control and power circuit diagrams, PLC card wiring diagrams, electrical panel design, etc. In projects where PLC is used, it is necessary for the learner to be able to design PLC control circuit diagrams, etc. and actually deliver them to the employer. Therefore, in this part of the golden period, we will work with Eplan software.