Register for Siemens Industrial Automation Online Classes

Dear friends, we would like to inform you that the Siemens Industrial Automation training course is currently being held online, taught by Engineer Ahmad Faraji.

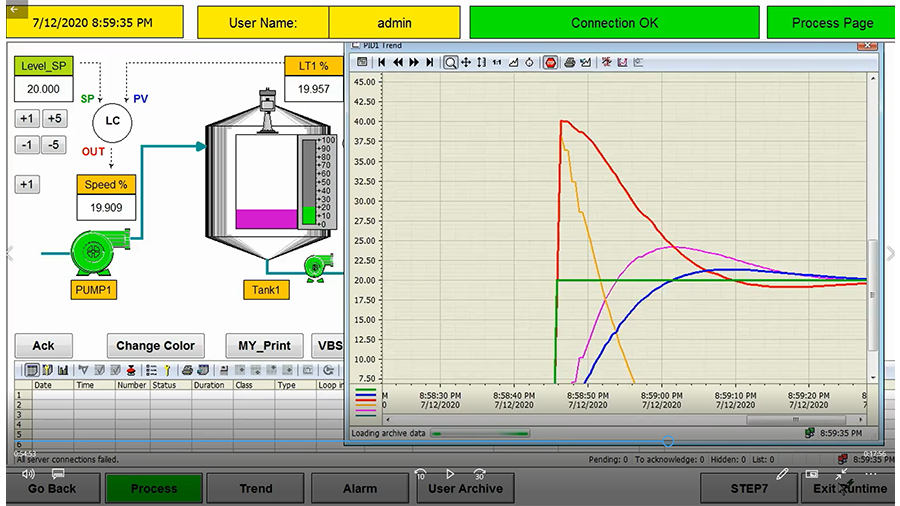

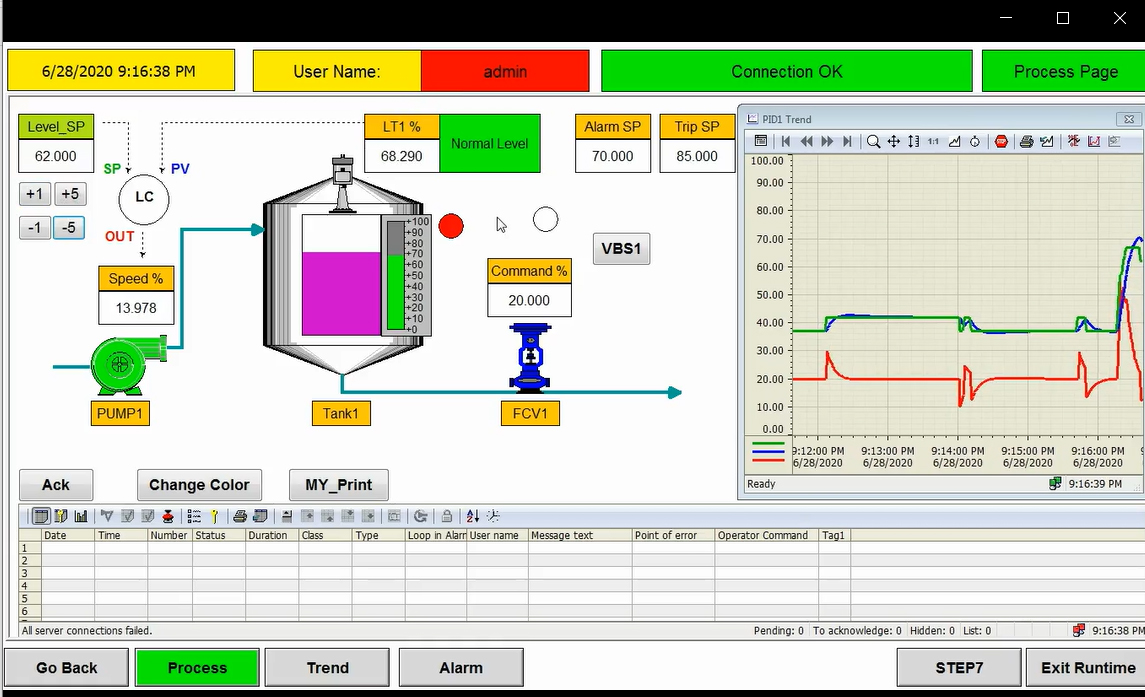

Figure (1) WinCC online course taught by Engineer Faraji

This training course includes the following:

- PLC S7 Basic Training (S7-300/400)

- Advanced PLC S7 Training (S7-300/400)

- WinCC SCADA Training

- PID Control training in STEP7 software

- PROFIBUS network training

Those interested can send a message to MrFaraji on WhatsApp at 09939643266 to coordinate registration.

Below, we will take a closer look at the syllabus of this training course and its objectives.

Course Name: Siemens Automation Online Course

Course instructor: Engineer Ahmad Faraji

Course duration: approximately 80 hours of educational videos

About the teacher:

- Author of industrial books on Siemens industrial automation training (10 volumes so far)

- Instructor of training courses in various industries in the country

- Executor of industrial automation projects in factories and industries

Click here to view the list of books authored and courses held by Engineer Ahmad Faraji .

Course Title (in order of execution)

1- Introduction to PLC S7-300/400 Siemens, introductory level

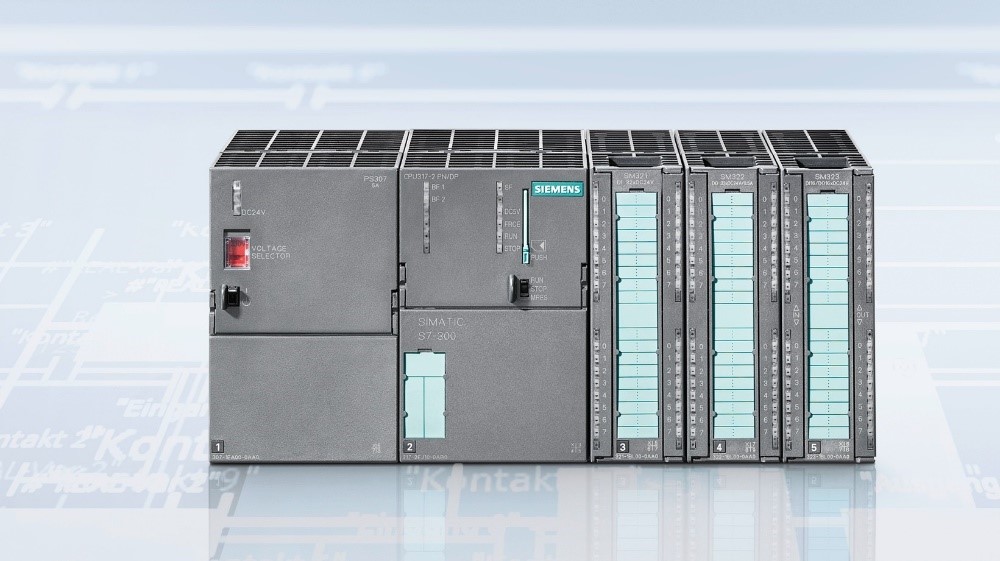

Among the important types of Siemens PLCs worldwide and in Iran, we can mention the two families of Siemens PLCs: S7-300 and S7-400.

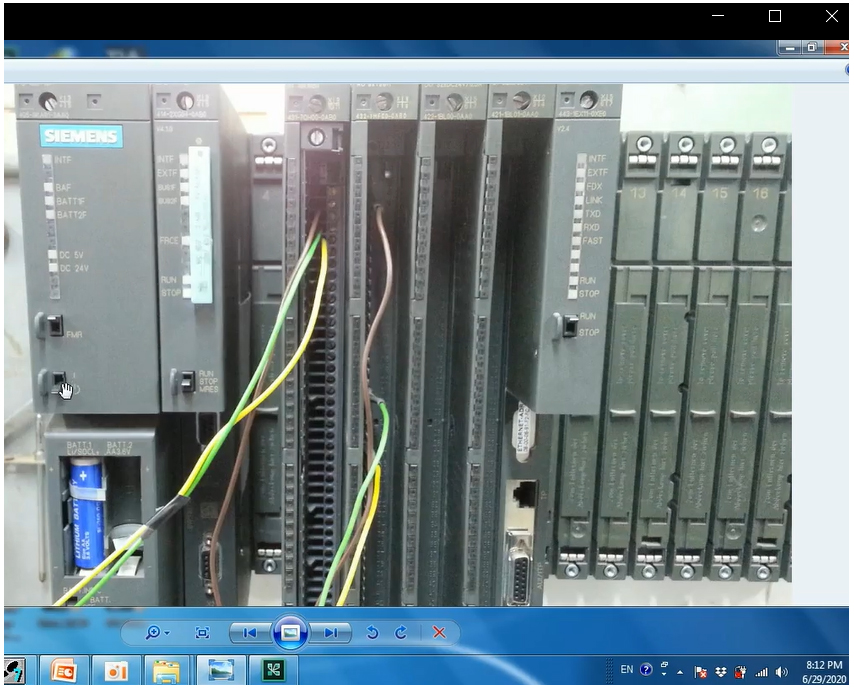

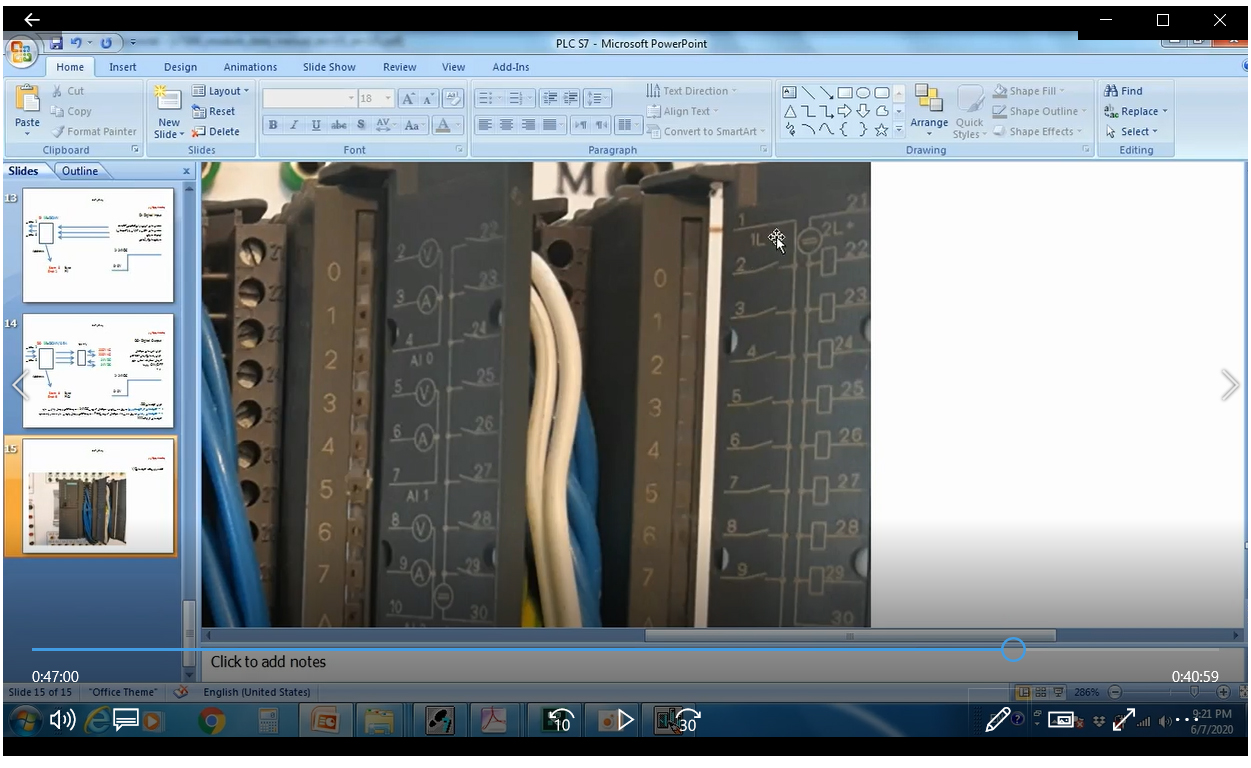

Figure (2) Image of S7-300 PLC

Figure (3) Image of PLC S7-400

These PLCs have been widely used in domestic industries as controllers for industrial production lines. Today, it is necessary for specialists (usually with different electrical backgrounds) to learn how to program and work with these PLCs because we still encounter this type of PLC in many industries and projects.

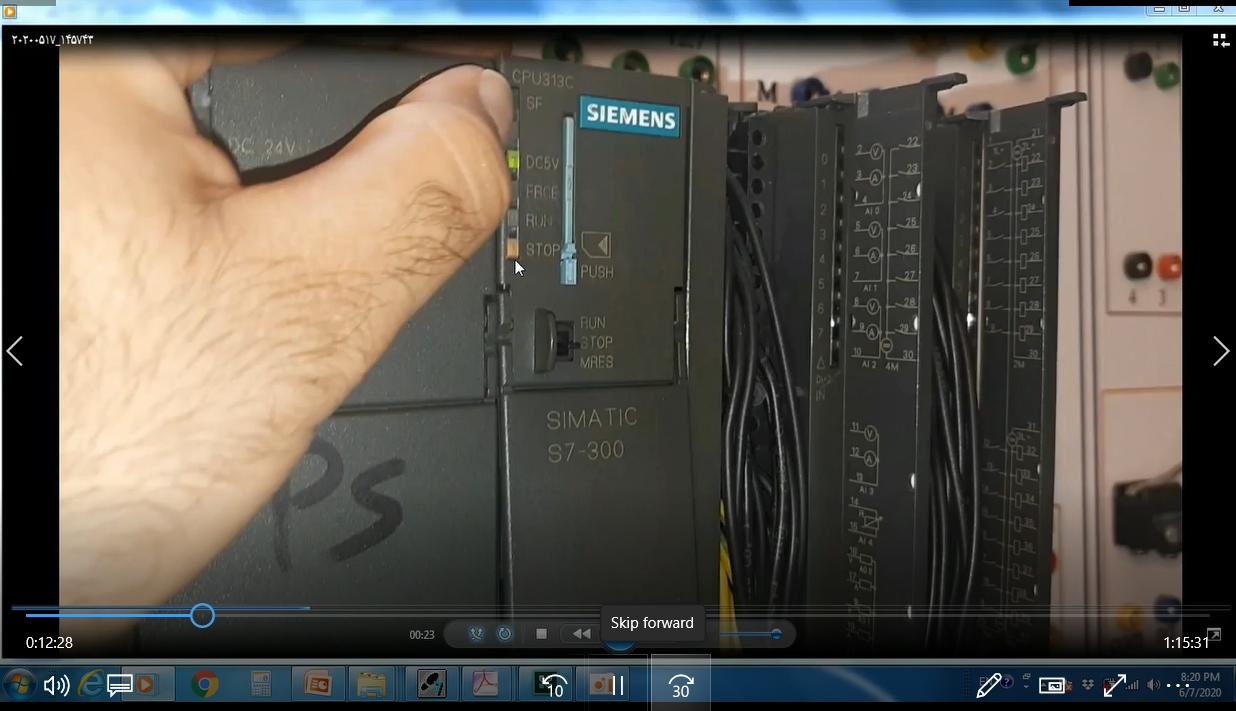

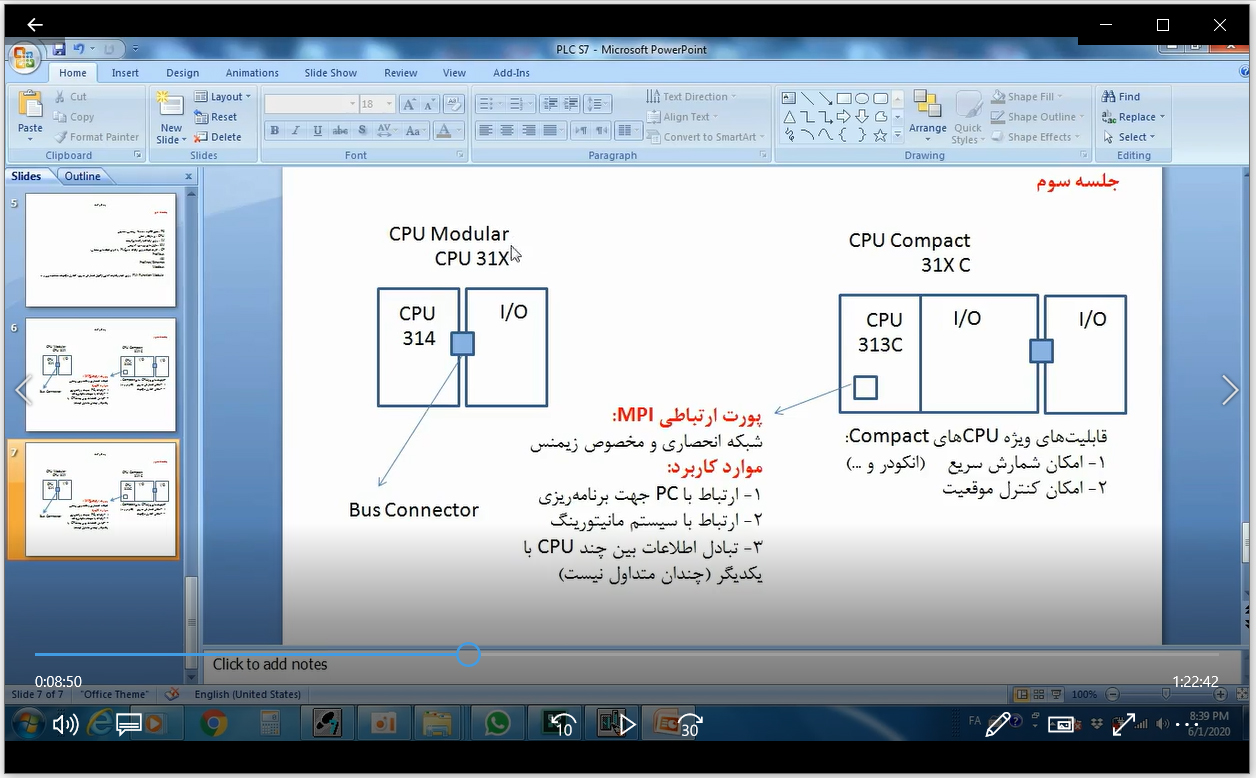

Introduction to PLC S7 Section Heading :

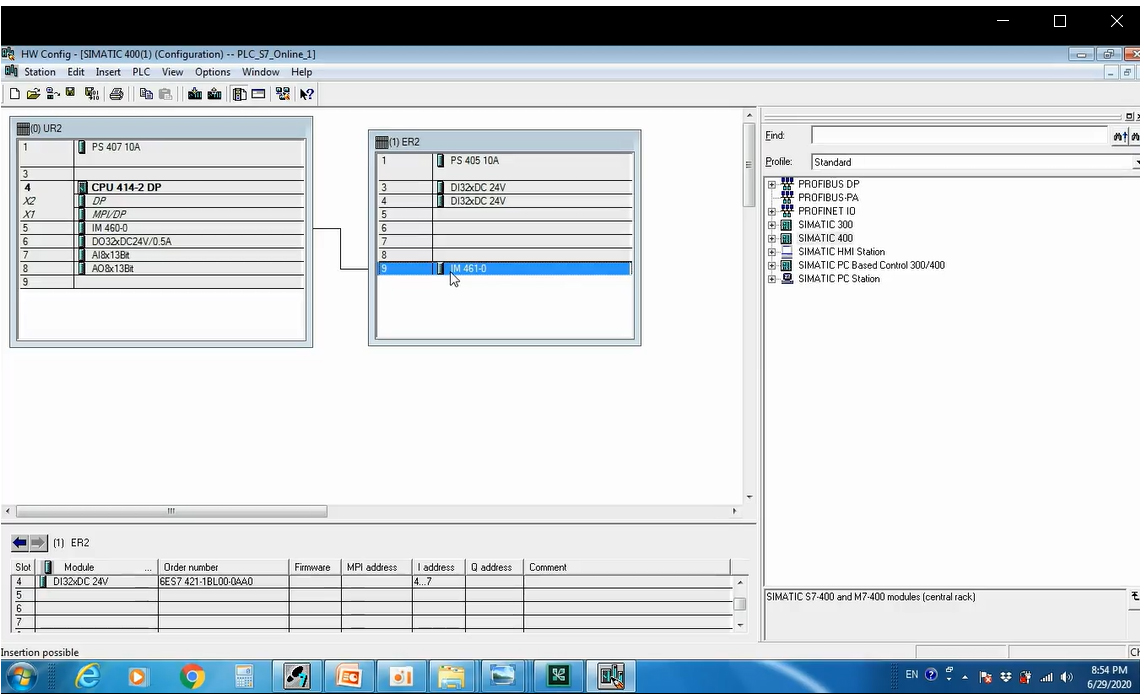

1- Shanakhet-Sakhtavzar PLC S7-300/400

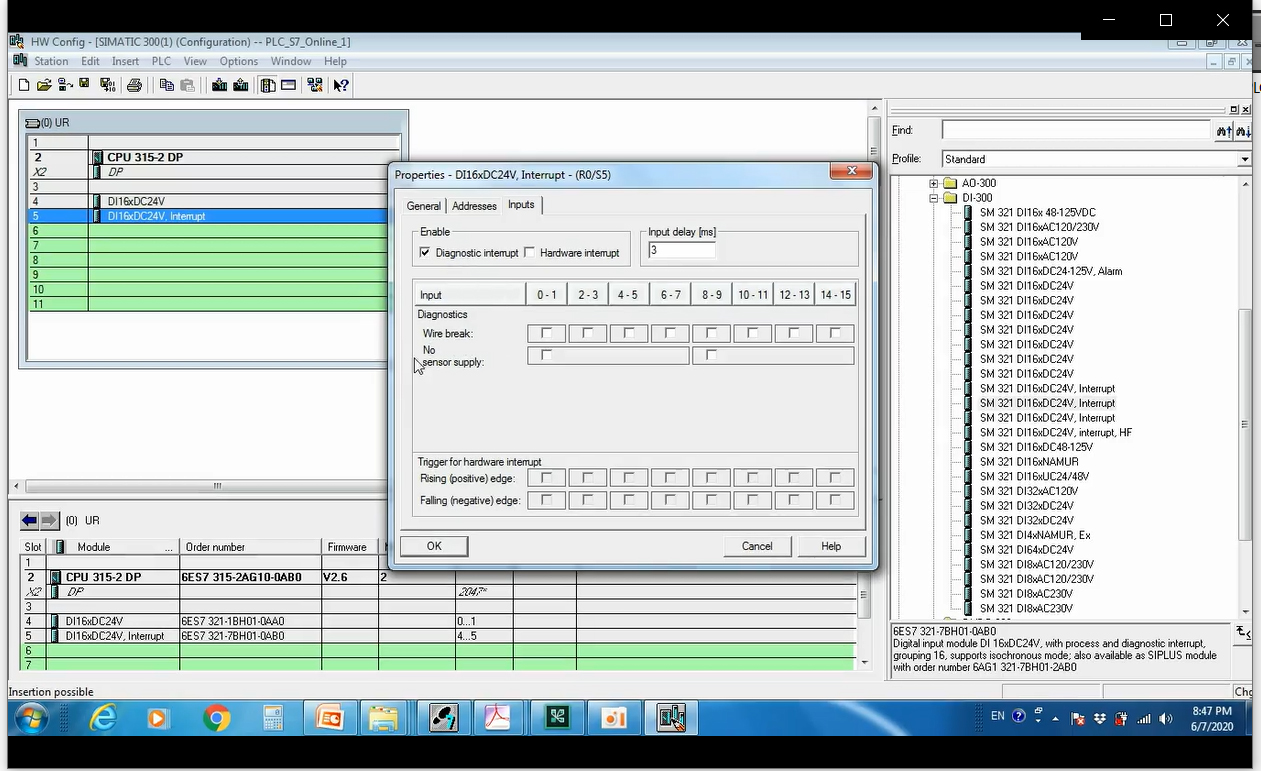

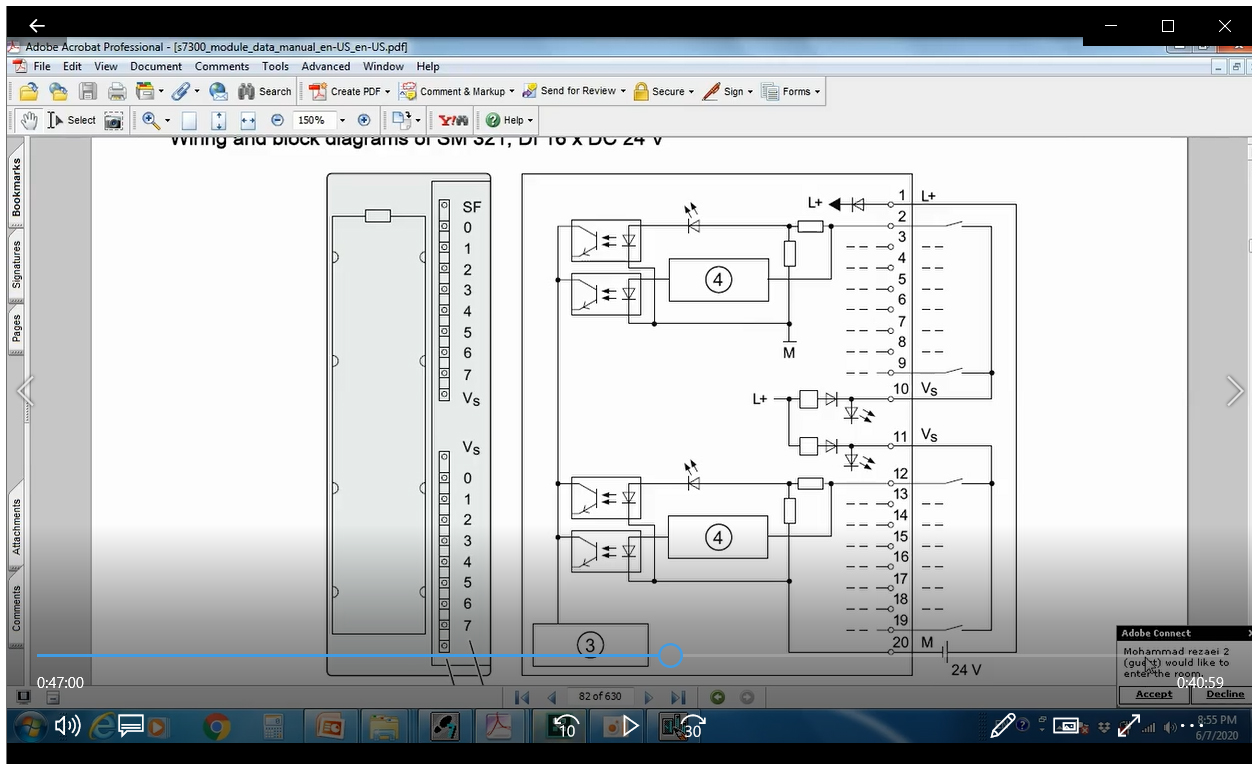

2- How to wire input/output cards (Signal Module)

3- How to configure PLC hardware

4- Familiarity with basic concepts in PLC such as:

- Checking input and output addressing in PLC

- Checking the CPU scan cycle in PLC

- Introduction to data typing in PLC

- Brief introduction to the types of PLC programming blocks

- Brief introduction to PLC programming languages

5- Working with Simatic Manager software

Includes project creation, hardware configuration, and card settings in the software environment.

6- Establishing practical communication with PLC S7-300 and PLC S7-400

7- Download and upload to PLC S7-300 and PLC S7-400

8- LAD programming in PLC S7-300 and PLC S7-400

9- Doing sample exercises and programming examples

Figure (4) Introduction to the various hardware parts of the S7-300 PLC

Figure (5) Introduction to the various hardware parts of the S7-300 PLC

Figure (6) Introduction to the various hardware parts of the S7-400 PLC

Figure (7) S7-400 PLC hardware configuration

Figure (8) S7-300 PLC hardware configuration

Figure (9) Checking the wiring diagram of input/output cards

Figure (10) Checking the wiring diagram of input/output cards

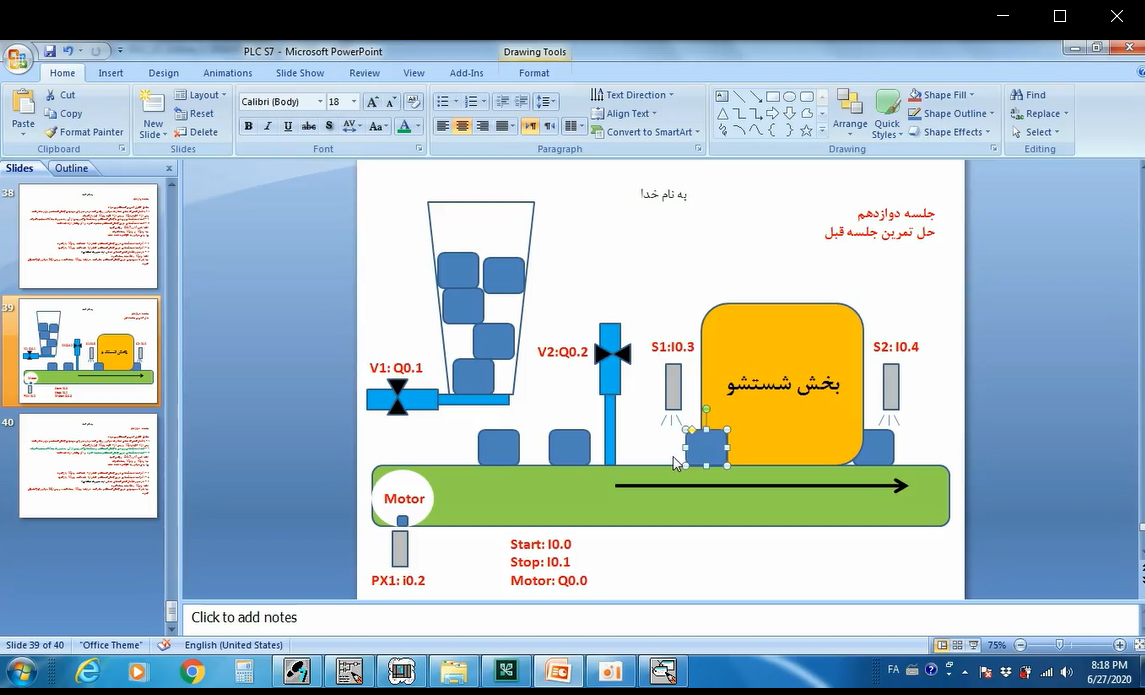

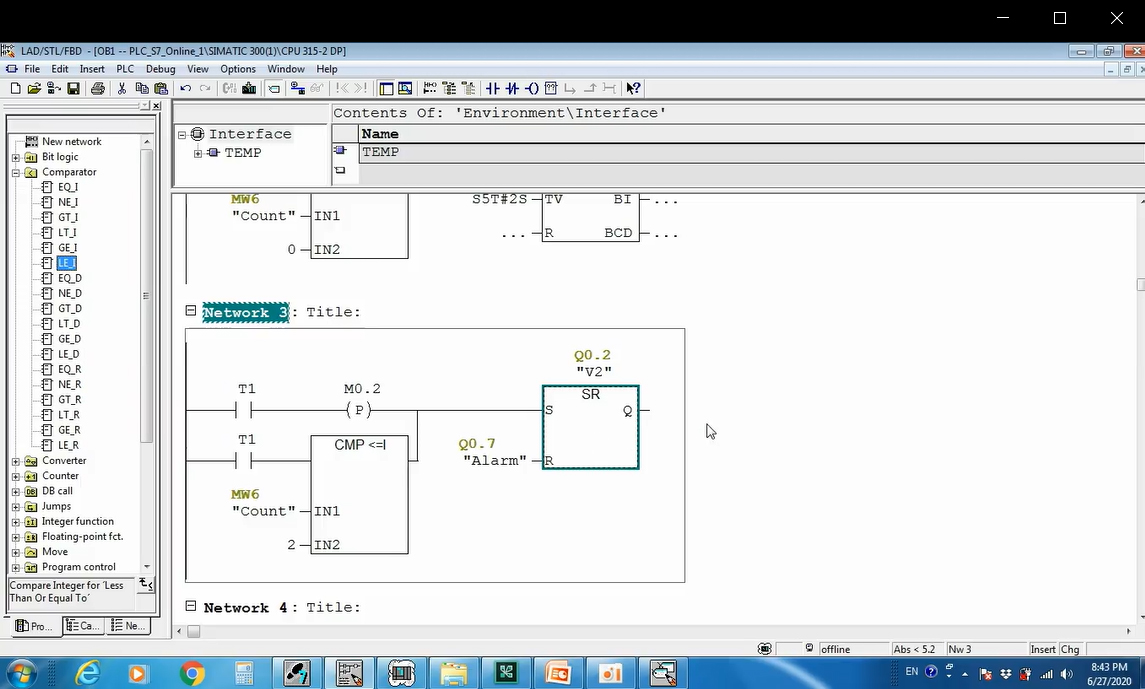

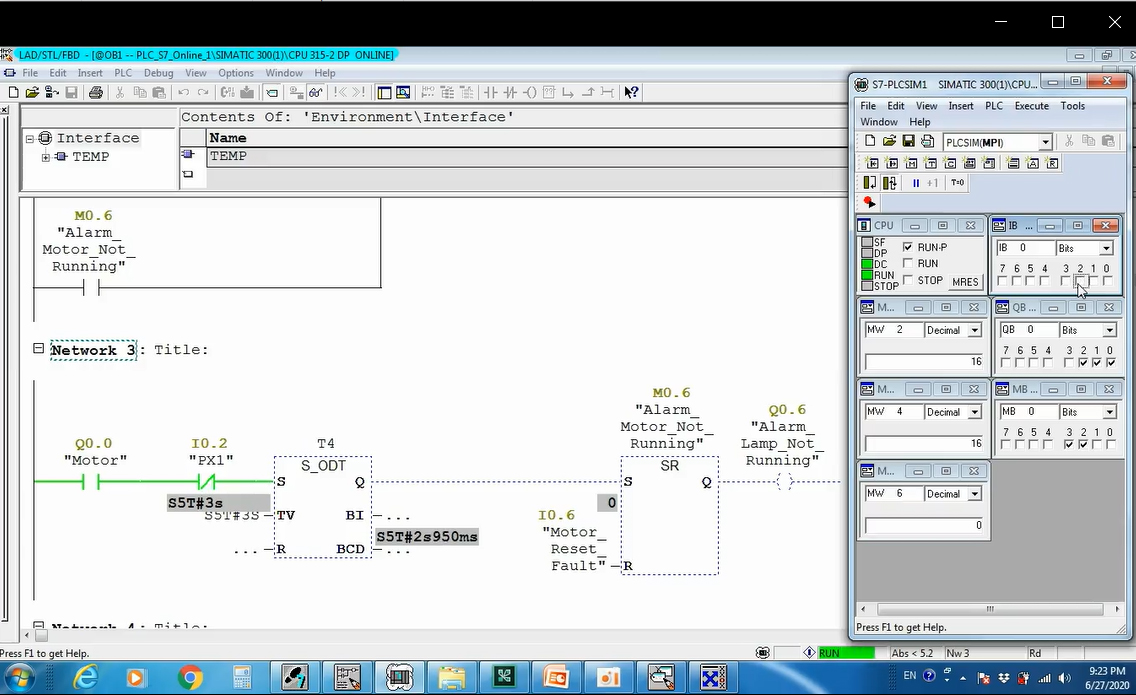

Figure (11) Example of programming exercises

Figure (12) Example of programming exercises

Figure (13) Example of programming exercises

Sample video of PLC S7 introductory online class

PLC S7-400 Hardware Configuration (Engineer Faraji’s Online Class)

https://www.aparat.com/v/2rKHs

Example of starting a motor using PLC S7 in the traditional way (Engineer Faraji’s online class)

https://www.aparat.com/v/CaWPO

2- Advanced level Siemens PLC S7-300/400 topic

After learners have become familiar with the hardware topics of PLC S7-300 and PLC S7-400 and have learned how to program in the basics; it is necessary to become familiar with advanced PLC topics . Our focus in this part of the Siemens online course is on the following topics:

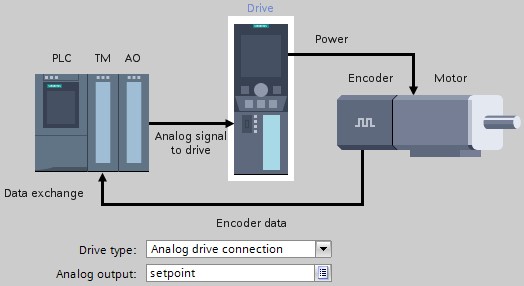

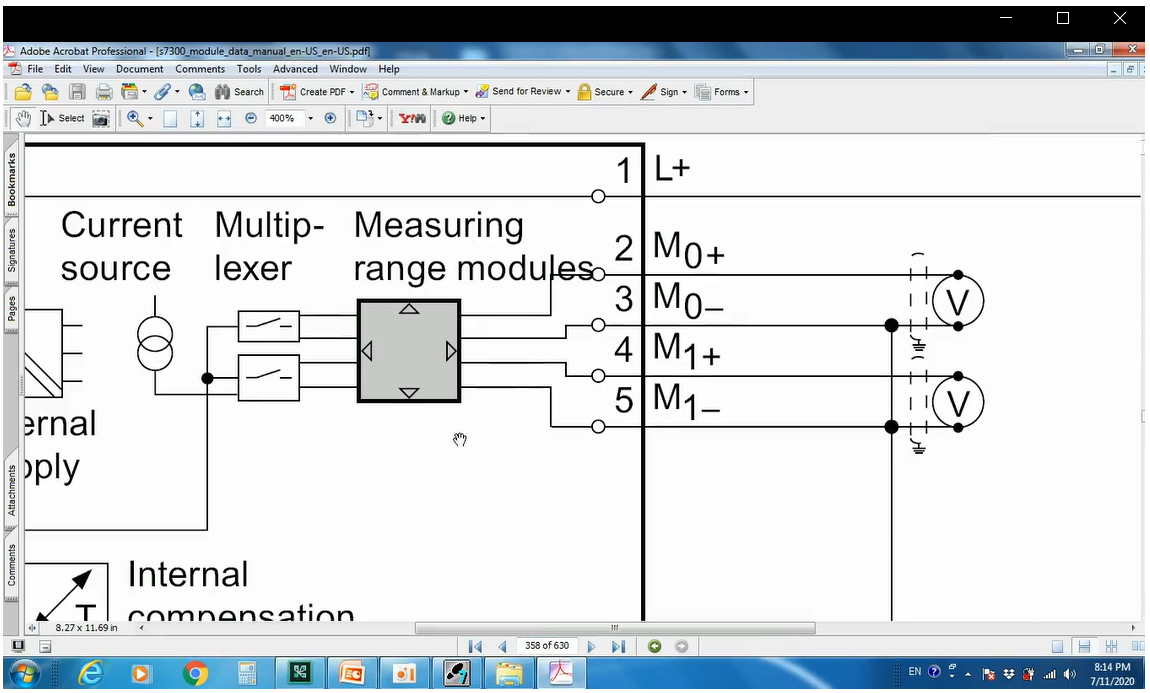

A- Working with analog signals

Unlike digital signals, analog signals are continuous in nature and are received from a variety of sensors and transmitters that measure continuous process quantities, such as temperature, pressure, flow, level transmitters, etc.

Figure (14) Several examples of temperature transmitters Figure (15) An example of an analog transmitter

Also, analog output signals are sent from the PLC to equipment such as drives, controllers, etc.

Figure (16)

B- Function , Function Block and Data Block Programming

In professional Siemens PLC programming, FC and FB blocks are used for the following tasks:

- Dividing the program into separate units

- Multiple calls of a block for repetitive programs

Data Blocks are also used to create structure in variables related to Setpoint and final values.

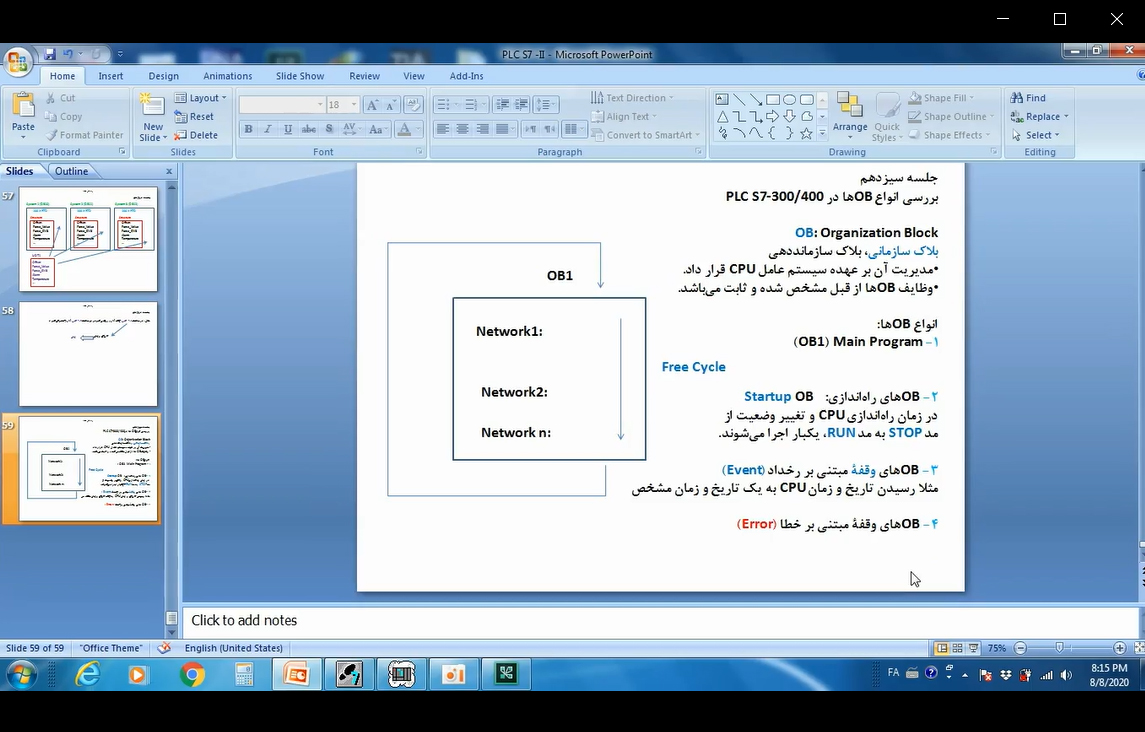

C- Working with various important OBs in Siemens

OB stands for Organization Block and represents the CPU organizational block, which is not managed by the programmer . In Siemens PLCs, different types of OBs are intended to perform different tasks. Among these OBs, the following can be mentioned:

- OB1: To execute the main program

- Startup OBs

- Cyclic OBs

- Date and time-based OBs

- Error OBs

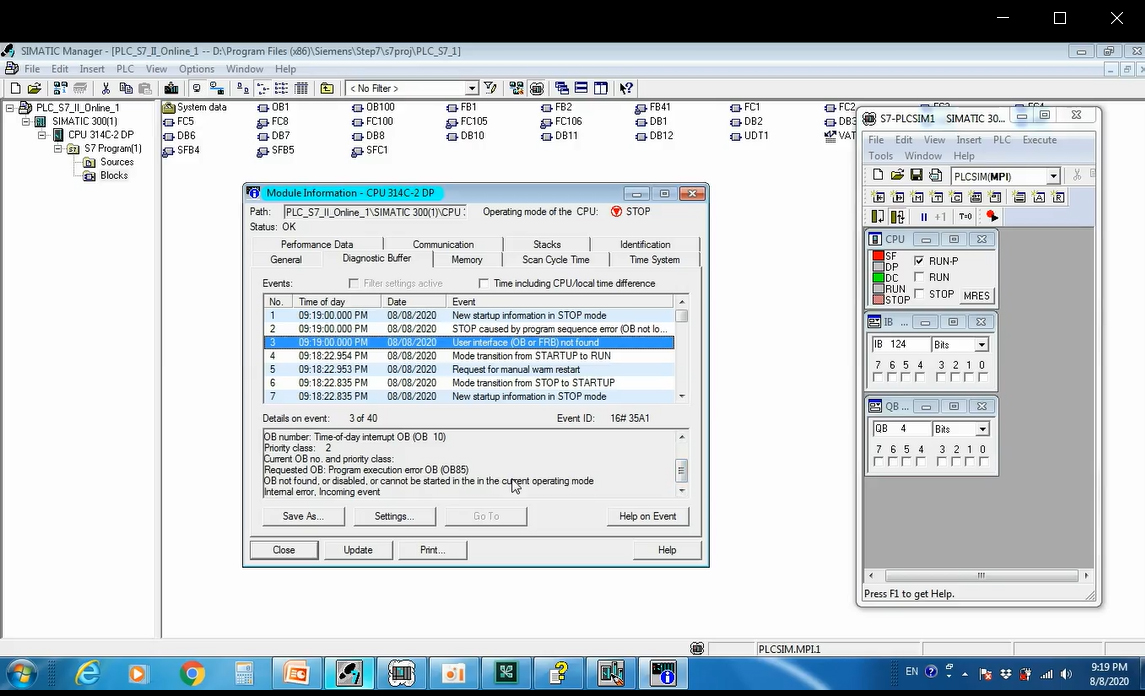

D- PLC testing and troubleshooting

In this section of the Siemens course, we will examine PLC testing and troubleshooting methods using software tools related to the Simatic Manager software. These tools include the following:

- VAT table and Force Table tool

- Diagnostic Buffer

- Open Online

- Reference Data

The information taught in this part of the course is very important and plays a very important role in troubleshooting programs and hardware such as PLCs, sensors, etc.

Figure (17) Checking the wiring of analog cards

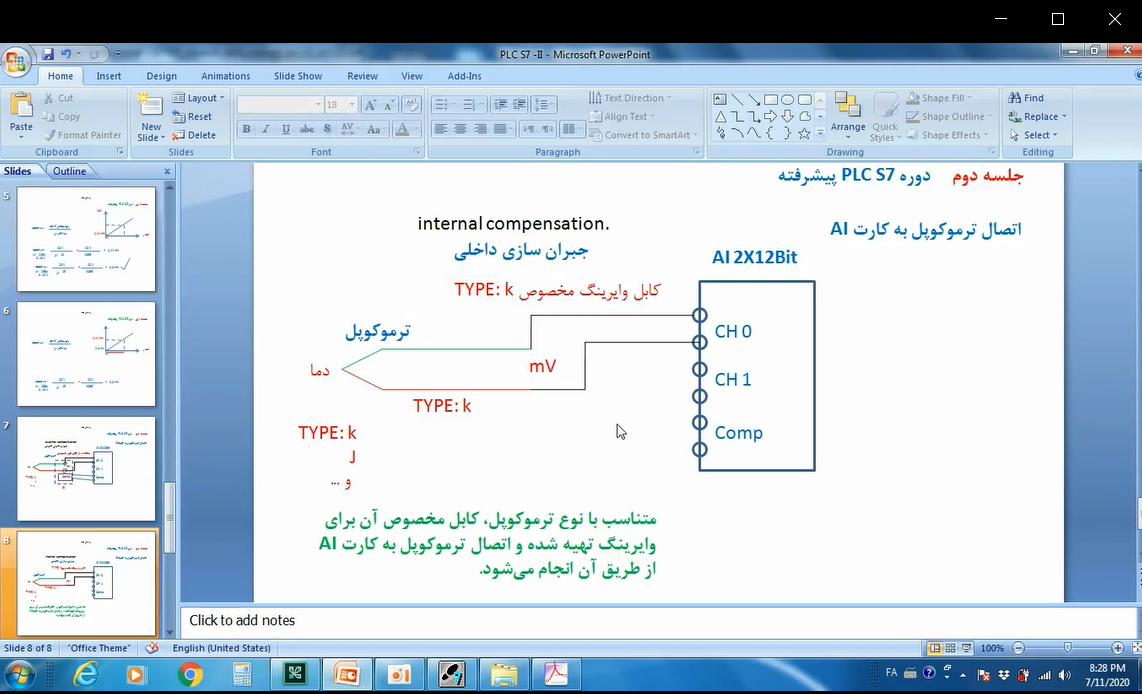

Figure (18) How to connect the thermocouple to the AI card in the PLC

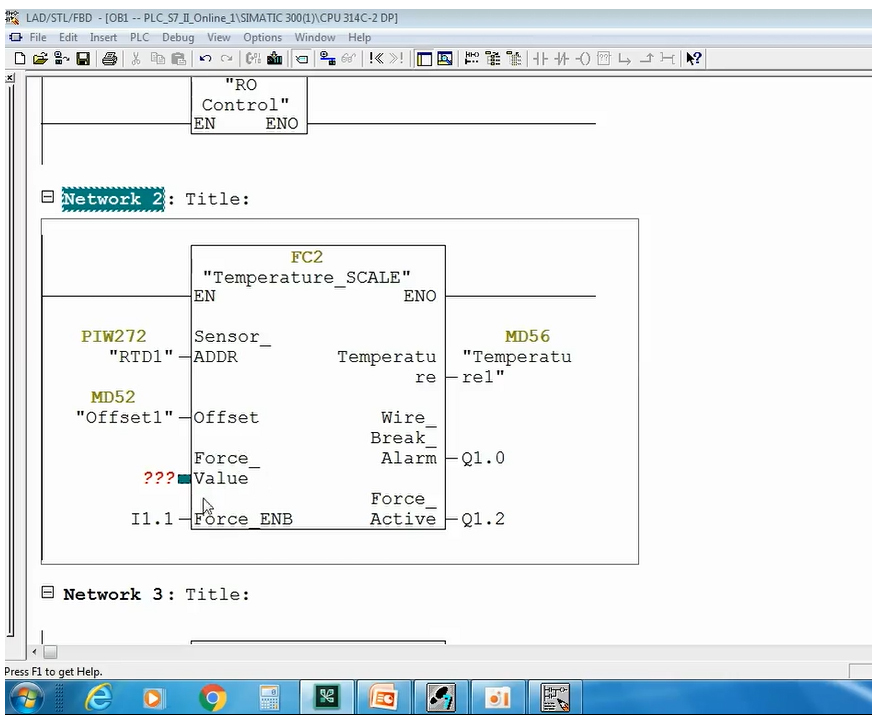

Figure (19) Training on working with a temperature transmitter

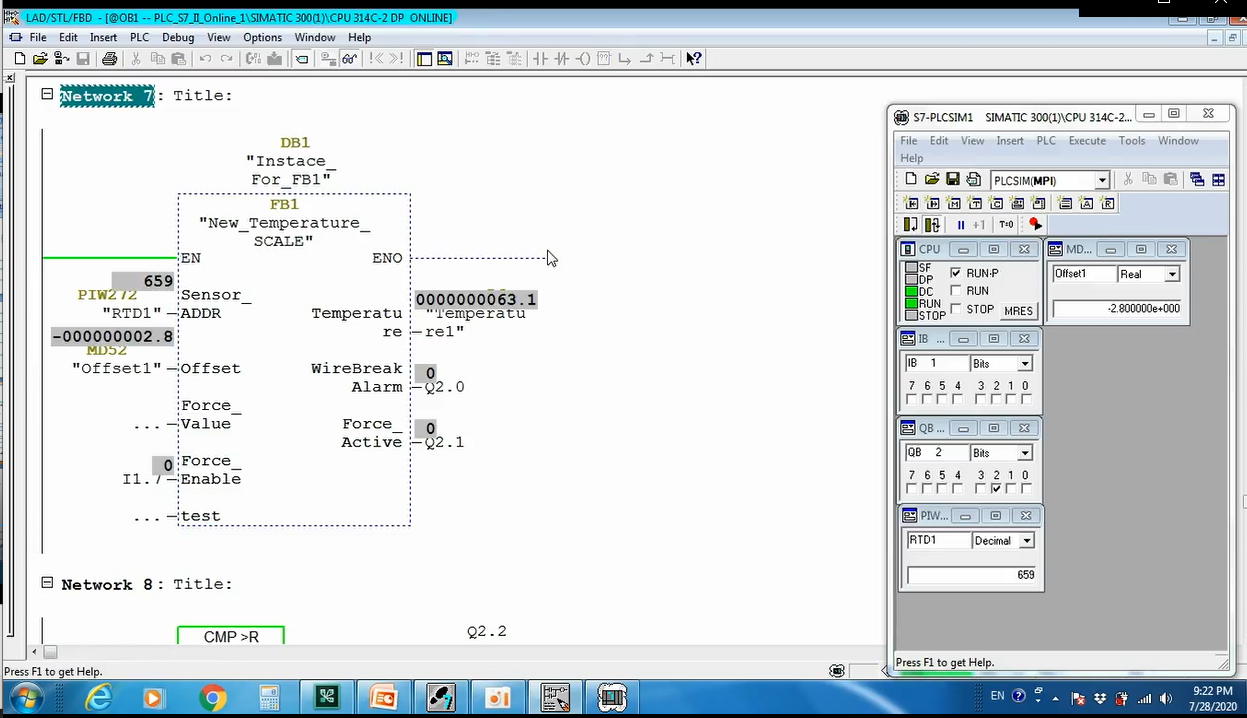

Figure (20) Function design for temperature scaling

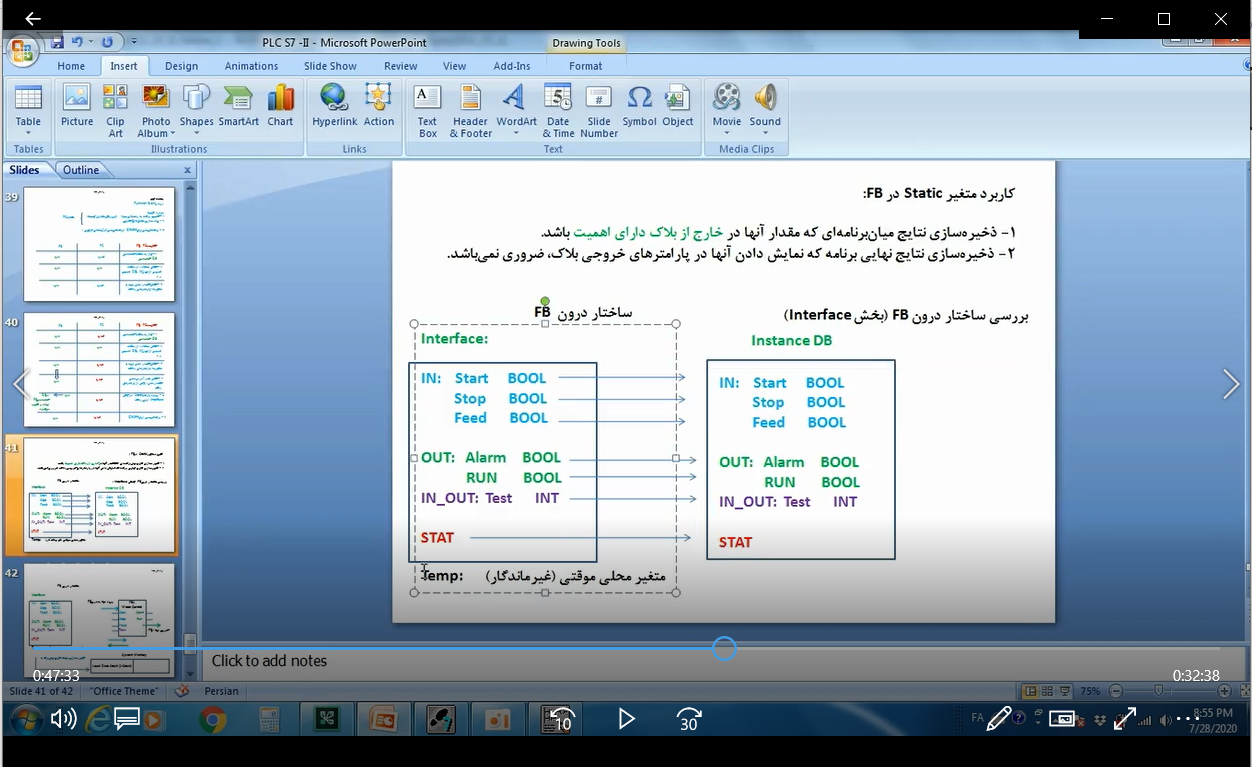

Figure (21) Examining the structure of functions and function blocks

Figure (22) Function block design for temperature

Figure (23) Review of OB types in PLC S7-300/400

Figure (24) PLC troubleshooting

Sample video of advanced PLC S7 online class

FB review in Siemens S7 PLC (Engineer Faraji’s online class)

https://www.aparat.com/v/RwvIX

Comparison of FC and FB (Engineer Faraji’s online class)

https://www.aparat.com/v/EtI10

3- WinCC SCADA section heading

WinCC SCADA software is one of the important and powerful Siemens software for designing computer-based monitoring systems. Using this software, a regular or industrial computer can be converted into a monitoring system, through which control commands can be sent to the PLC and process or production line information can be displayed graphically.

Figure (25) WinCC SCADA software

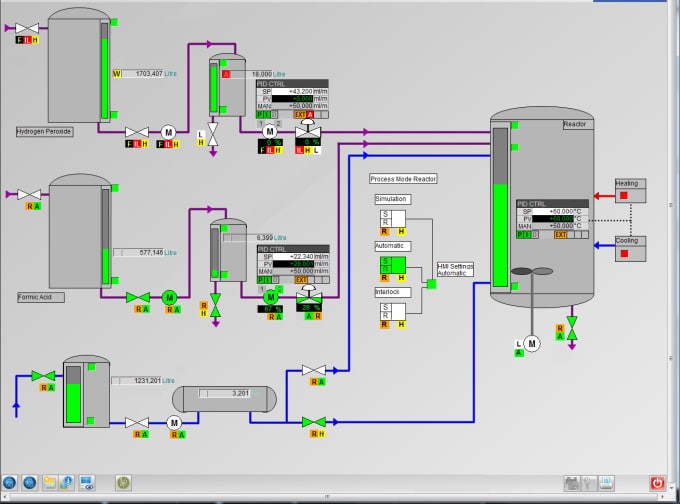

Figure (26) Runtime environment related to WinCC SCADA

Things that are taught to learners in the WinCC course:

- Familiarity with the monitoring system and its functions

- Introduction to types of industrial monitoring systems

- Familiarity with various monitoring system implementation methods (Single User, Multi User, Distributed System)

- Understanding how to communicate between WinCC and PLC S7

- Familiarity with the types of communication drivers in the Tag Management section

- Creating communication drivers, configuring communication drivers, getting to know tag types

- Working with the Graphic Designer environment, performing simple exercises, configuring simple processes and testing them

- Using process tags integrated with STEP7

- Introduction to dynamicization methods

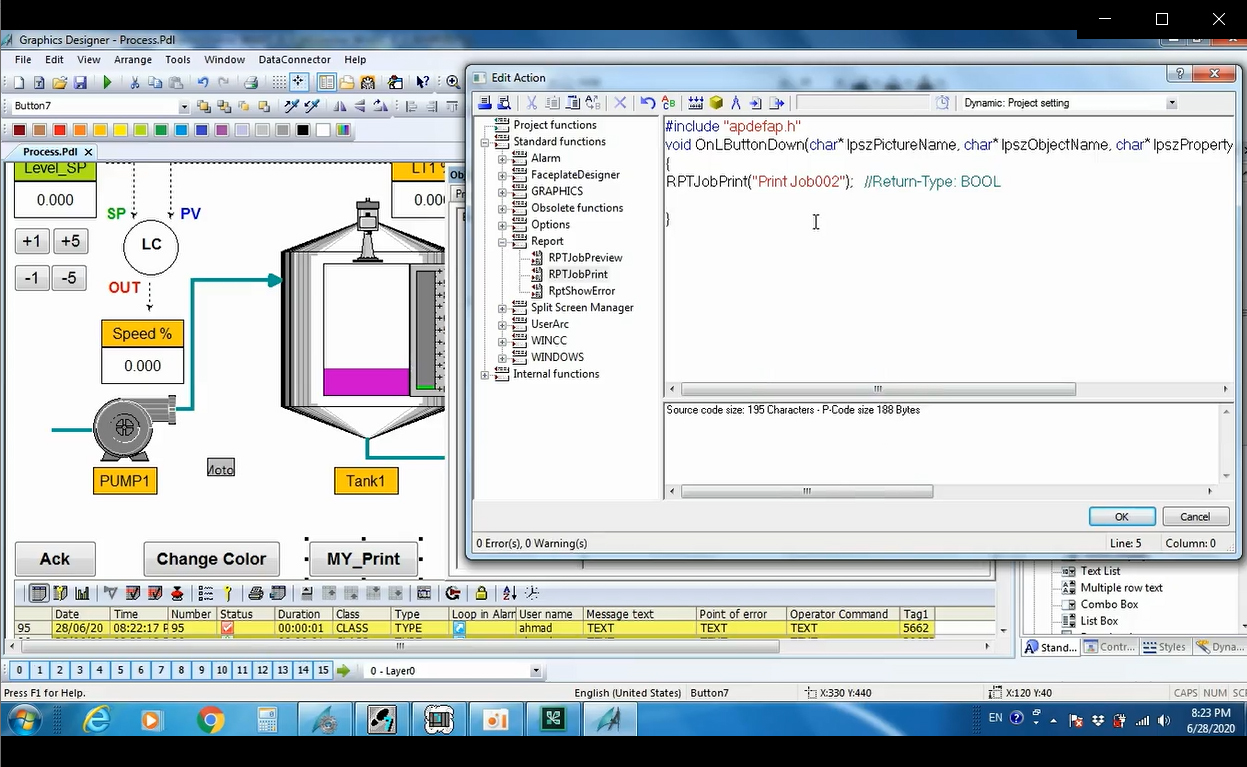

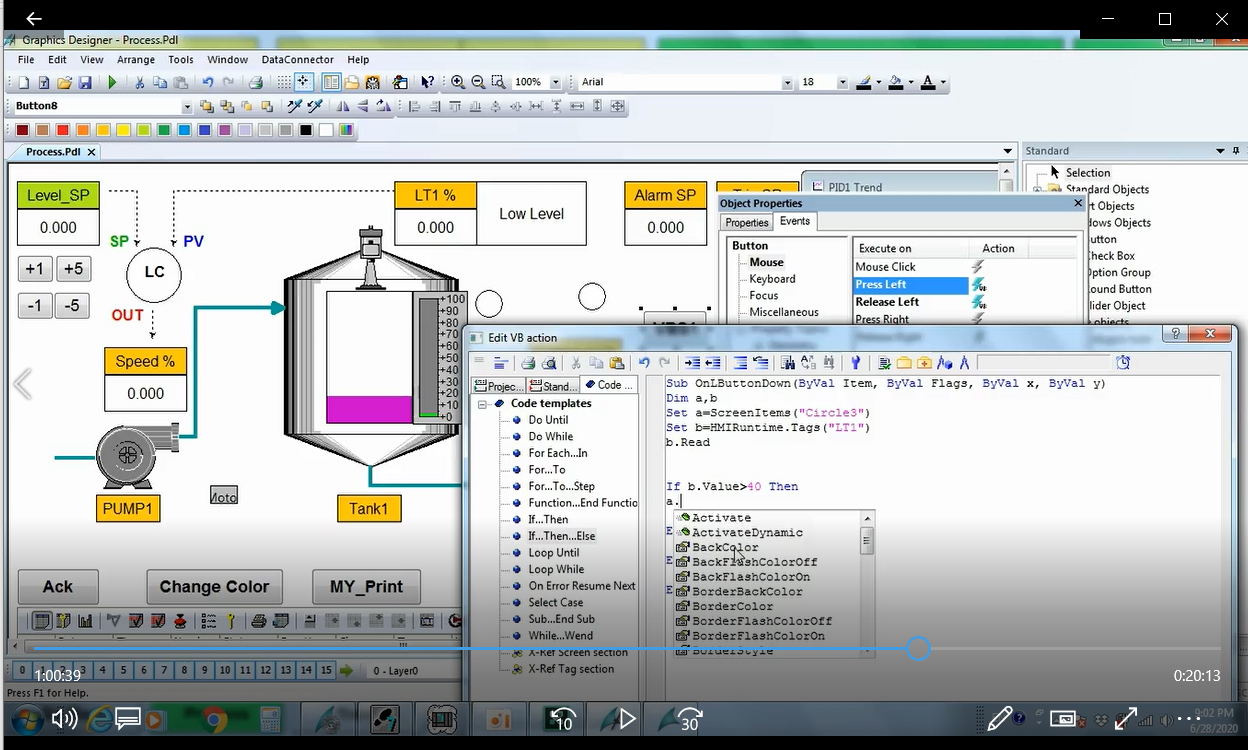

- Familiarity with C and VBS language commands in WinCC and performing various sample exercises

- Alarm management with Alarm logging

- Archive management using Tag logging and display in Trend and Table formats

- Managing users using User Administrator

- Familiarity with other parts of WinCC such as OS Project Editor, Picture Tree Manager, etc.

- Carrying out various sample projects and exercises using WinCC software

Figure (27) Example of programming in WinCC in C language

Figure (28) Example of programming in WinCC in VBS language

Figure (29) Example of a project defined in the WinCC SCADA online course

Sample video of WinCC SCADA online class (Instructor-Engineer Faraji)

https://www.aparat.com/v/s7Rw8

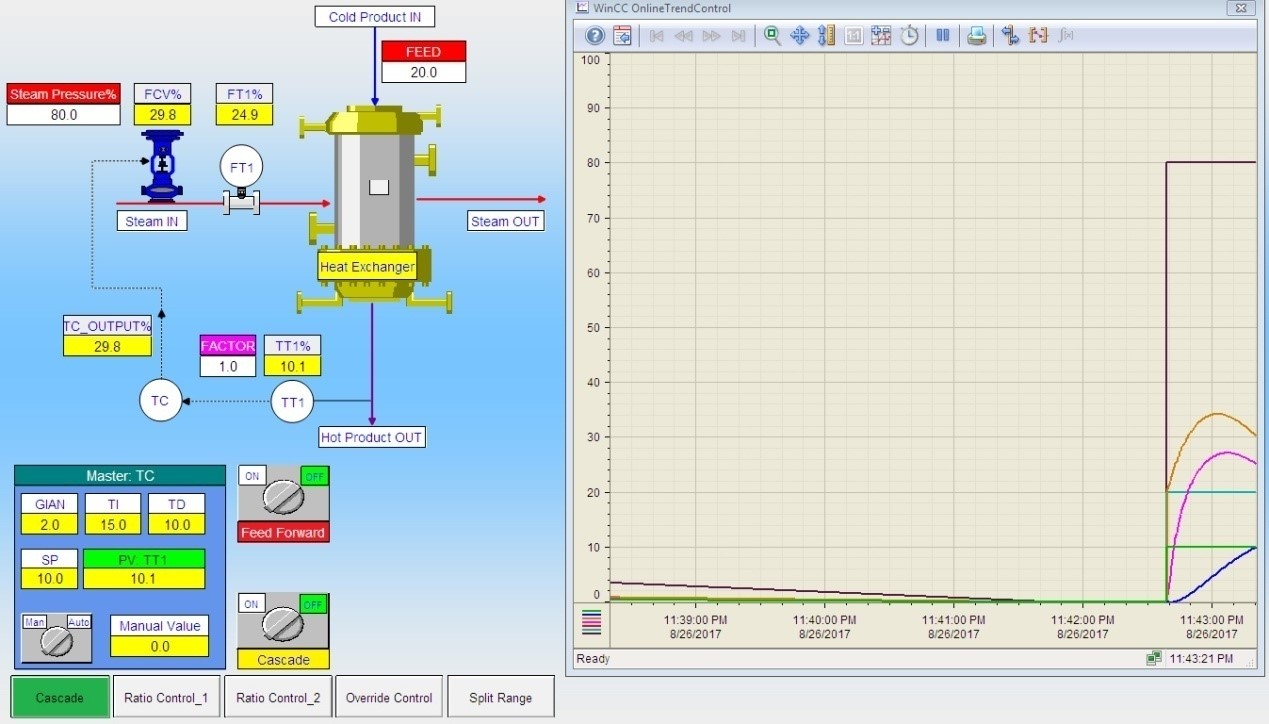

4- PID Control Training Topic

PID is considered as a control method in closed-loop systems for precise adjustment of process quantities such as temperature, pressure, flow, level, etc. Siemens PLC types for PID control have various blocks and functions that are essential for industry professionals to learn. Therefore, in the online course, we will examine PID blocks in Simatic Manager software in detail.

The things we work on in this section include:

1- Familiarity with various industrial systems and industrial control concepts

2- Familiarity with control loop methods (P, PI, PD and PID)

3- Understanding the dynamic behavior of industrial processes

4- Familiarity with loop tuning methods

6- Familiarity with implementing PID Control in STEP7 software

7- Review of Siemens standard blocks including FB41, FB43, FB42, FB58 and FB59

8- Implementing continuous control using FB41 (implementing an example of controlling the inlet pressure of a tank and an example of controlling the level in a tank)

9- Implementing two-stage control using the combination of FB41 and FB43 (implementing the temperature control example)

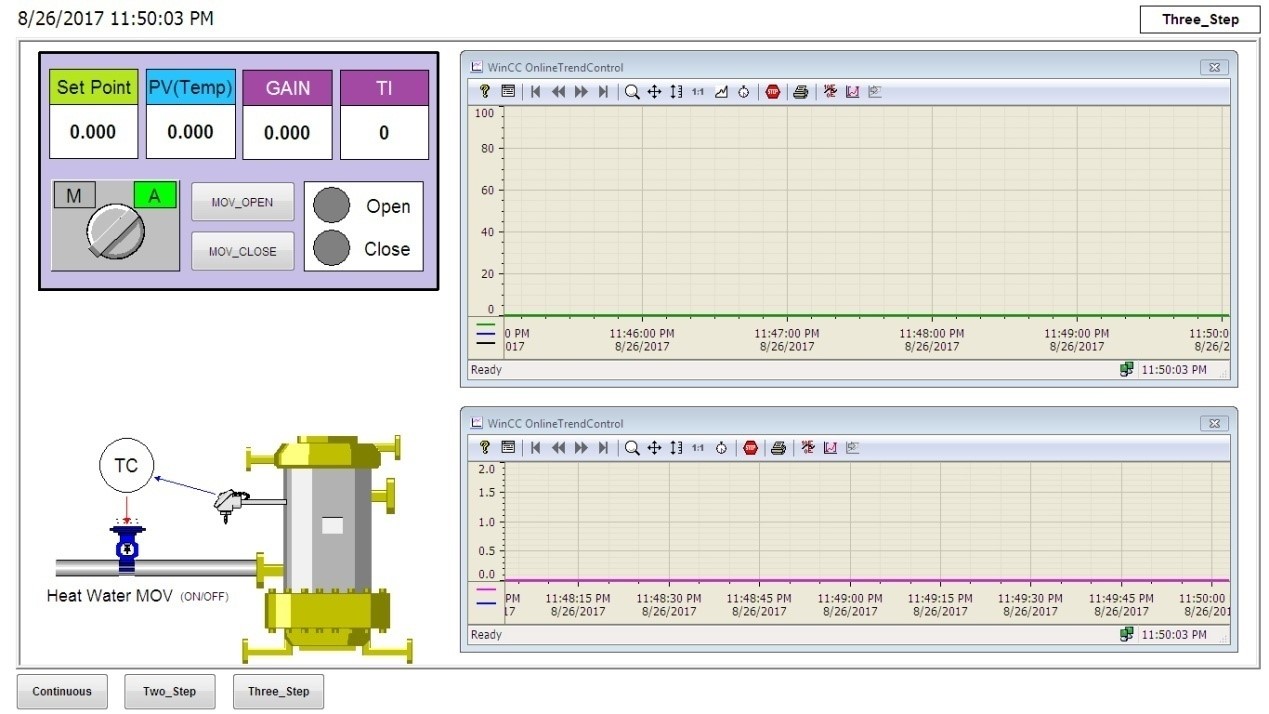

9- Implementing three-stage control using two On/OFF operators using the combination of FB41 and FB43 (exemplifying temperature regulation in a heat exchanger)

10- Implementing three-stage control (motor valve) using FB42 (implementing temperature control example)

11- Implementing temperature control using FB58 and FB59 (Example of temperature control in burner and heat exchanger)

12- Reviewing the Cascade Control strategy and performing an exercise (heat exchanger)

13- Review of Feed Forward Control Strategy and Conduct an Exercise (Heat Exchanger)

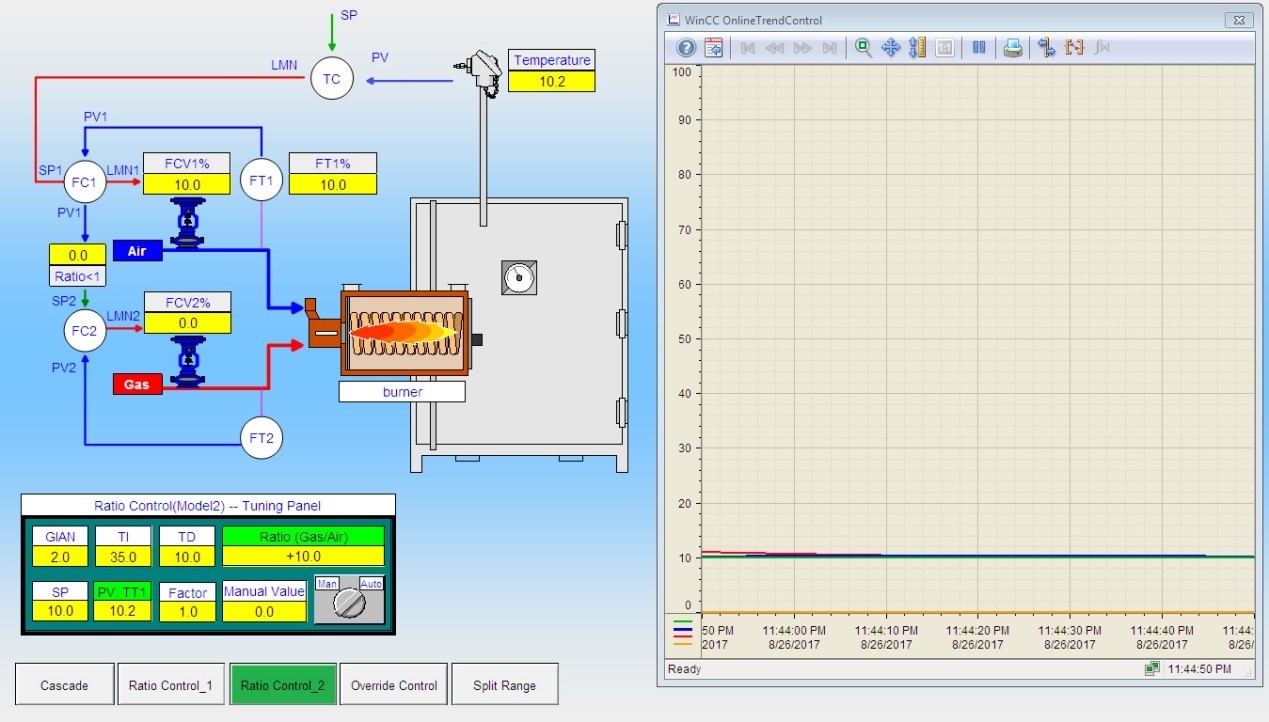

14- Investigating different methods of implementing the Ratio Control strategy and performing an exercise (controlling a gas burner)

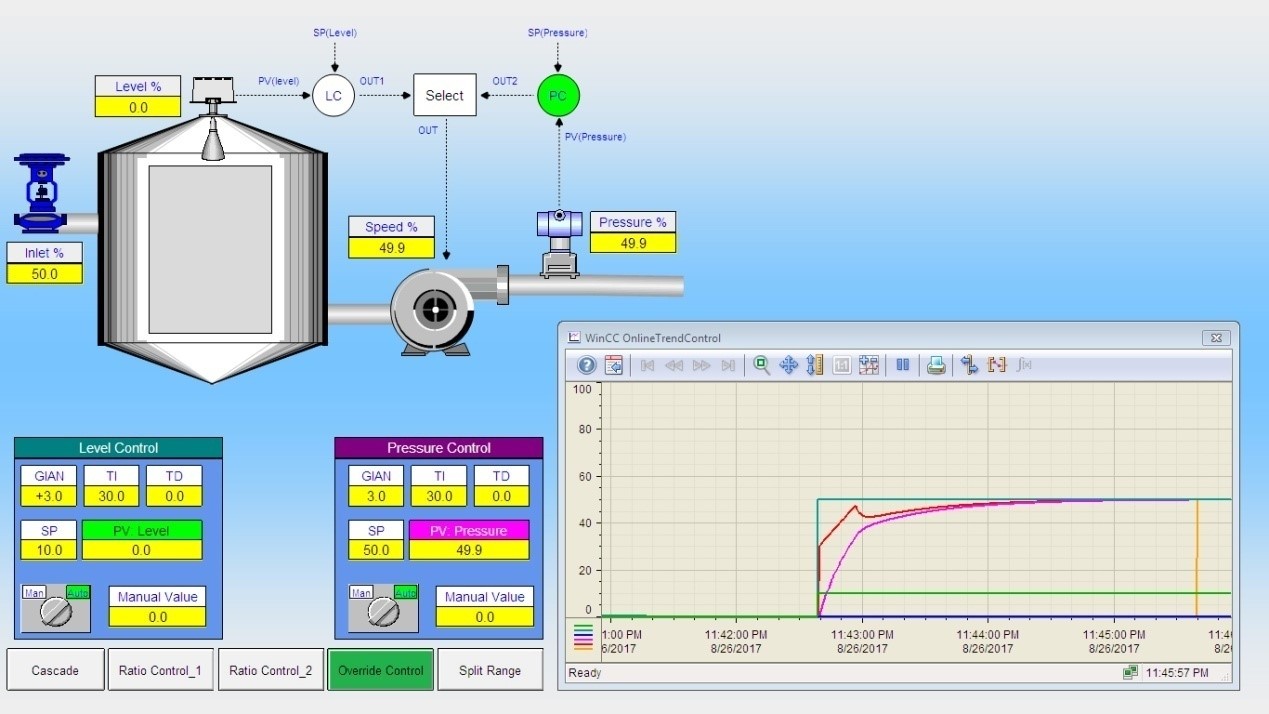

15- Reviewing the Override Control strategy and performing an exercise (pressure and level control of a tank)

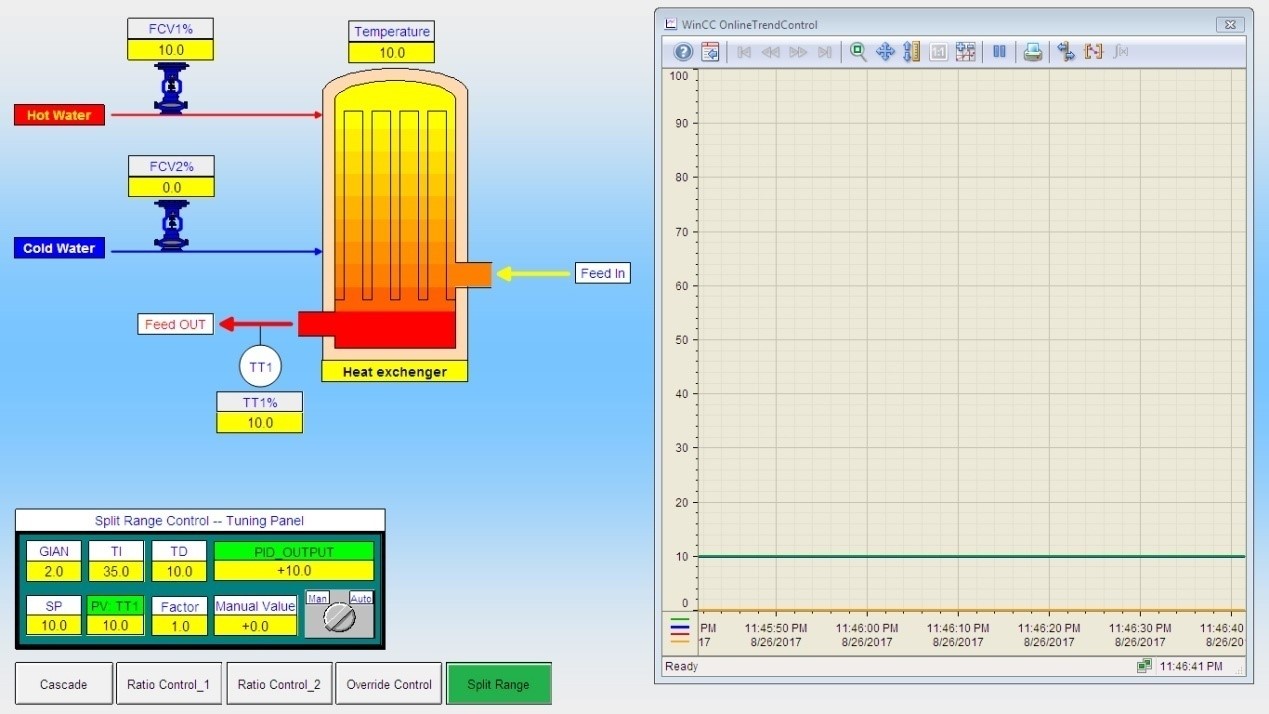

16- Review the Split Range Control strategy and perform an exercise (temperature control in a heat exchanger)

Some exercises to be performed during the course

Figure (30) Sample exercises of the PID online section

Figure (31) Example of exercises in the online PID section

Figure (32) Example of exercises in the online PID section

Figure (33) Example of exercises in the online PID section

Figure (34) Example of exercises in the online PID section

Figure (35) Example of exercises in the online PID section

Sample video of PID Control online class (Instructor-Engineer Faraji)

Investigating the effect of PID parameters in Siemens S7 PLC (Teaching by Engineer Faraji)

https://www.aparat.com/v/Im3xk

5- PROFIBUS network implementation course in Siemens PLC (recorded in video)

License Terms: Single user on one system only

Course duration: 13.5 useful hours

Instructor: Engineer Ahmad Faraji

Course title:

1- Introduction to the Profibus DP network and its applications

2- Understanding the hardware components of the Profibus DP network, such as cables, connectors, repeaters, etc.

3- Master/Slave configuration and programming in the DP network in the SIMATIC MANAGER software environment

4- Implementing Master/Slave communication with ET200M in two ways: using the DP port on the CPU and the CP card.

5- Programming the Micromaster drive using Starter software

6- Implementing Master/Slave communication with the Micromaster drive in two ways: DP port on the CPU and CP card.

7- Communication between two PLCs using the Master-Islave method

8- Communication between two PLCs as Client-Server using the S7-300 Profibus CP card and the S7-Connection and FDL services, as well as communication between PLCs S7-400 and S7-300.

9- Communication between two PLCs using DP/DP Coupler and its programming

10- Practical review of how to use Repeater in Profibus DP network

11- Troubleshooting the Profibus network

Practical equipment:

PLC S7-300/400 DP

Drive Micromaster + CP Profibus

ET200M

Repeater

DP/DP COUPLER

Introduction video of the PROFIBUS course topic

https://www.aparat.com/v/vewkl

Sample course video titled ET200M review on PROFIBUS network

https://www.aparat.com/v/3oeHM

Sample course video titled How to work with Starter software and Micromaster drive. Recorded video of the Profibus course.

https://www.aparat.com/v/NKs2m